Kitchen knives made in Germany are often the first choice of professional chefs and home cooks. They are sharp and durable. So what makes them so good? The answer lies in the steel used to make the tools. From the common X50CrMoV15 to the advanced Friodur, each steel has its own unique advantages. However, there is one often overlooked detail that could change the way you think about your favorite knife…

Types of Tool Steel Used in German Knives

German cutlery’s global reputation stems from centuries of metallurgical craftsmanship. Unlike mass-produced blades, these knives prioritize functional artistry – where rust-resistant chromium meets carbon’s edge stability. Take Wüsthof’s iconic chef knives: their secret lies not just in steel formulas, but in how blacksmiths layer and temper metals like a culinary samurai sword. From slicing heirloom tomatoes to deboning poultry, each steel variant (X50CrMoV15, Friodur, etc.) tells a story of balancing aggression and finesse.

| Steel Type | Carbon (%) | Chromium (%) | Molybdenum (%) | Vanadium (%) | Nitrogen (%) | Hardness (HRC) | Key Features |

|---|---|---|---|---|---|---|---|

| X50CrMoV15 | 0.5 | 15 | Small amounts | Small amounts | — | 55-57 | Balances sharpness, corrosion resistance, and durability. Ideal for daily kitchen tasks. |

| 1.4116 | 0.45-0.55 | 14-15 | 0.5-0.8 | 0.1-0.2 | — | 54-56 | Easy to maintain with excellent rust resistance. Popular in mid-range German knives. |

| X30CrMoV15 | 0.3 | 15 | Small amounts | Small amounts | — | 52-54 | Affordable option with decent durability and corrosion resistance. Softer than premium steels. |

| Friodur | — | — | — | — | — | 57-58 | Zwilling’s cryogenically treated steel (-70°C). Enhanced hardness and corrosion resistance. Premium. |

| 14C28N | 0.62 | 14 | — | — | 0.11 | Up to 62 | Swedish-origin steel with exceptional toughness. Used in high-end German knives. |

German knife makers focus on balancing toughness, corrosion resistance, and ease of maintenance. The moderate hardness of these steels makes them easier to sharpen compared to the harder steels used in Japanese knives.

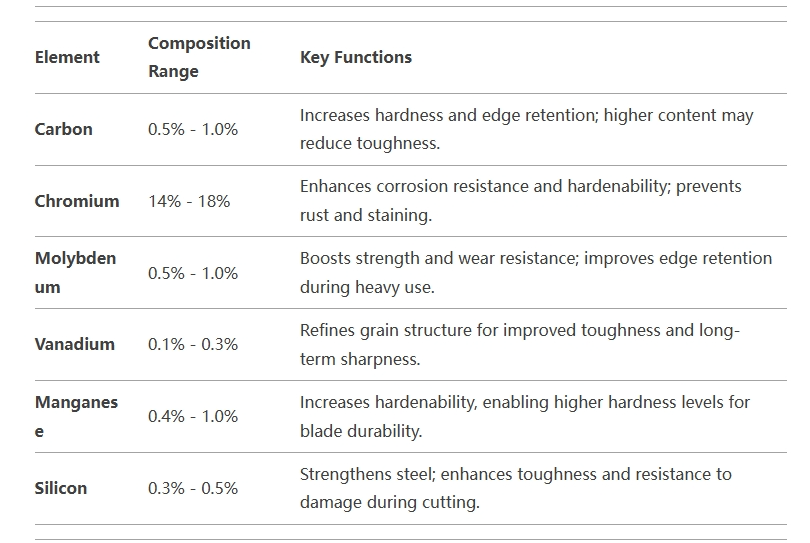

Common Alloying Elements

Behind every German knife’s “click” through a carrot is calculated chemistry. Tool steels here aren’t random mixes – they’re molecular recipes. For instance, molybdenum acts like microscopic armor against wear, while vanadium tightens the steel’s “grain” for cleaner cuts. Heat treatment is equally vital: Zwilling’s cryo-freezing method (-70°C) locks in a 57-58 HRC hardness – imagine ice-forged metal that shrugs off acidic onion juices. It’s this lab-meets-anvil approach that lets a blade dice 10,000 herbs without surrendering its bite.

Popular German Knife Brands and Their Tool Steel

German-made knives stand out for their sharp performance, long-lasting durability, and ability to maintain an edge. The key factor is the type of tool steel they use, and this truly makes a big difference. I recommend checking out some of the top German knife brands and the steels that make them essential for any kitchen.

| Brand | Tool Steel Used | Composition & Key Properties | Notable Series/Features |

|---|---|---|---|

| Wüsthof | X50CrMoV15 | – 0.5% C, 15% Cr, Mo/V – High edge retention, corrosion resistance |

Most standard knives; durable and low-maintenance |

| Zwilling J.A. Henckels | X50CrMoV15 (standard) FC61 (high-end) |

– X50CrMoV15: Similar to Wüsthof – FC61 (AEB-L equivalent): Higher hardness (58–60 HRC), enhanced edge retention |

Zwilling Pro series; professional-grade sharpness |

| Messermeister | X50CrMoV15 (standard) X65CrMo14 (premium) |

– X50CrMoV15: Balanced performance – X65CrMo14: Higher carbon (0.65%) for superior edge retention |

Elite series; ideal for precision cutting |

| F. Dick | X55CrMoV14 | – 0.55% C, 14% Cr – Slightly higher carbon than X50CrMoV15 for better hardness (56–58 HRC) |

Durable kitchen knives; popular among home cooks |

| Güde | C75W (Alpha series) | – High-carbon steel (0.75% C) – Exceptional sharpness but requires rust prevention |

Alpha series; prioritizes razor-sharp edges |

| Robert Herder | C75 (standard) X50CrMoV15 (select models) |

– C75: High-carbon edge retention – X50CrMoV15: Stainless steel option with moderate edge retention |

Mix of traditional (C75) and corrosion-resistant (X50CrMoV15) models |

Conclusion

Most German knife brands use X50CrMoV15 or similar steels, which offer a good balance of toughness and ease of sharpening. Premium lines, however, often feature specialized steels like FC61, X65CrMo14, or C75W for even better performance. If you’re looking for superior durability and edge retention, these premium steels are worth considering.

Care and Maintenance

Owning a German knife is akin to inheriting a blacksmith’s legacy – my Zwilling Pro 8″ Chef’s Knife still bears the faint hammer marks from Solingen’s forge. To preserve its spirit, I ritualistically hone the blade after each use with a 20° ceramic rod, avoiding dishwashers like garlic breath. Years of julienning ginger and portioning brisket have taught me: a well-cared-for blade doesn’t just slice; it sings, its HRC 58 edge catching the light like a Damascus waterfall. Treat it right, and it’ll outlast your cast-iron skillet.

| Maintenance Step | Key Actions |

|---|---|

| Cleaning | – Hand-wash with mild soap and warm water immediately after use. – Dry thoroughly with a soft cloth to prevent spots/rust. – Avoid soaking or leaving in water. – Use non-abrasive cleaners only. |

| Storage | – Store in a knife block, magnetic strip, or blade guards. – Separate blades to prevent dulling. – Keep in a dry environment. |

| Sharpening | – Hone regularly with a honing steel (15–20° angle per side). – Use whetstones or professional sharpening if edges become dull. |

| Rust Prevention | – Apply food-grade mineral oil to carbon steel blades. – Wipe dry after each use. – Never leave wet/dirty. |

| Handle Care | – Oil wooden handles periodically with mineral oil. – Avoid soaking wooden handles (risk of cracking). – Clean plastic handles with mild soap/water. |

| What to Avoid | – Dishwasher use (heat/detergent damage). – Cutting on hard surfaces (glass/metal/stone). – Prolonged contact with acidic foods. – Extreme temperature changes. |

Advantages of German Knife Tool Steel

There’s a reason Michelin-starred chefs call German steel a “prosthetic hand.” When I dice onions with my Wüsthof Classic, the high-carbon X50CrMoV15 steel becomes a synaptic extension – zero resistance through paper-thin shavings, no wrist fatigue after 50 lbs of squash. The chromium’s rust resistance? Think of it as the knife’s immune system, battling acidic tomato assaults. Unlike brittle Japanese blades demanding babying, these tools thrive in chaos – bone-in chicken one minute, chiffonade basil the next, always reborn with a leather strop’s kiss.

Considerations When Choosing German Knives

Choosing the right German knife is all about how it feels in my hand and the types of meals I want to prepare. It’s not just about the blade. It’s about finding a knife that fits your kitchen style, one that makes every chop, slice, and dice feel easy.

Blade Material

German knives are often made from high-carbon stainless steel, like X50CrMoV15. This material is strong, resistant to rust, and holds its edge well. It offers the durability needed for tough jobs while keeping the blade sharp.

Blade Thickness

A key feature of German knives is their thicker blades. With a thickness of 2.5-3mm, they’re built to handle tougher tasks, making them perfect for chopping, slicing, and cutting through dense foods.

Edge Angle

German knives have a wider edge angle, usually between 17.5 and 20 degrees per side. This makes them durable and able to handle tough jobs without chipping. However, it does mean the edge isn’t as sharp as the finer angles found in Japanese knives.

Handle Material and Tang Construction

The handle plays an important role in comfort and grip. German knives come with various handle materials, such as synthetic POM, wood, and stainless steel. It’s important to choose one that feels comfortable in your hand. A full tang, where the blade runs through the handle, adds balance and durability.

Bolster and Rockwell Hardness

German knives often feature a bolster, which adds weight and protects your hand. The Rockwell hardness is typically between 56-58 HRC. This strikes a good balance between edge retention and ease of sharpening, making German knives easier to maintain than the harder Japanese knives.

Brand Reputation and Intended Use

Trusted German brands like Wüsthof, Zwilling J.A. Henckels, and Messermeister are known for their high-quality knives. Think about what you’ll use the knife for. German knives are great for heavy-duty cutting, chopping, and general kitchen tasks, so they are perfect for everyday use.

Maintenance Requirements

One of the benefits of German knives is their ease of maintenance. They are easier to sharpen and maintain compared to harder knives like those made with Japanese steels. If you want a low-maintenance knife that still performs well, German knives are a solid choice.

summary

Choosing the right German knife is about more than just the blade. It’s about finding a tool that suits your style and feels comfortable in your hand. A good German knife can make every kitchen task easier. With proper care, it can last a lifetime and help you prepare countless meals with precision. The right steel and balance are essential. You’ll find everything you need for a great experience.