For global service

Stainless Steel Manufacturer

workers

Company area/acres

Workshop area/SQM

Product Quantity

FCS Stainless Steel OEM Factory

Stainless Steel

Welcome to Fu Cheng Tool Steel, your leading provider of premium stainless steel in China since 2007. With 18 years of specialized experience in the production of stainless steel and tool steel, we pride ourselves on delivering high-performance materials tailored to meet the diverse needs of our clients.

Our Stainless Steel Products

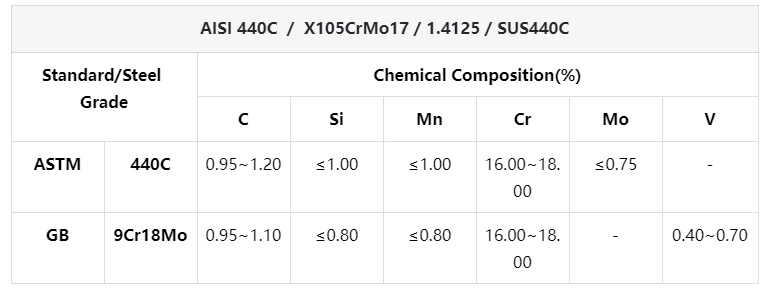

AISI 440C/X105CrMo17/1.4125 / SUS440C: Renowned for its high wear resistance and excellent hardness, AISI 440C stainless steel is ideal for applications requiring durability and precision. Its corrosion resistance, combined with the ability to achieve high hardness, makes it a top choice for various industrial applications.

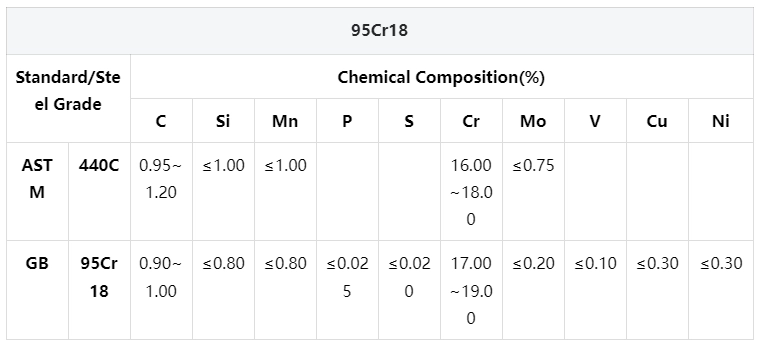

95 Cr18: This stainless steel grade is known for its impressive combination of strength and toughness, along with excellent corrosion resistance. It is particularly suited for manufacturing cutting tools and various dies, where performance and reliability are paramount.

Custom Stainless Steel Solutions: At Fu Cheng Tool Steel, we understand that every project is unique. That’s why we offer the option to customize the type of stainless steel to meet your specific requirements. Our dedicated team of engineers will work closely with you to ensure that you receive the ideal material for your application.

Excellent properties of stainless steel

Corrosion resistance

Stainless steel with its chromium, nickel and other alloy elements, the formation of a dense oxide film on the surface, effectively resist the erosion of various chemical substances, whether in the wet Marine environment, or strong acid and alkali industrial scenes, can maintain stable performance, greatly extending the service life of equipment and products.

High strength and toughness

It has excellent strength, can withstand huge pressure and impact force, and has good toughness, is not easy to break, and can still maintain good shape and performance under complex machining and high strength conditions.

Good processing performance

It is easy to carry out various processing processes such as cutting, welding, forging, etc., which can meet the diversified needs of different customers for product shape and accuracy, providing great convenience for industrial manufacturing.

Beauty and hygiene

The surface is smooth and bright, with modern metallic luster, not only improves the appearance quality of the product, but also is not easy to breed bacteria, in line with health standards, and is widely used in food, medical and other industries with high health requirements.

Extensive manufacturing experience:

Responsive Supply System:

Competitive Pricing:

Production facilities are fully equipped:

SIZE RANGE

440C

STAINLESS STEEL GRADES

APPLICATION

Germany 1.4125 / X105CrMo17

- Tool manufacturing: Kitchen tools, industrial cutting tools (such as drills, milling cutters), surgical instruments, etc., thanks to its high hardness and easy cutting properties.

- Mechanical parts: bearings, gears, shafts, suitable for high load and high-speed operating environments.

- Automotive industry: brake discs, exhaust system components, transmission components to meet the needs of high temperature and corrosive environments.

- Chemical equipment: valves, pumps, pipelines, corrosion resistance to weak acids and organic solvents.

- Automatic processing: Easy cutting steel for automatic lathes for the production of precision parts.

Japan SUS440C/USA 440C/China 9Cr18Mo

- Precision bearings: Bearings in ships, aircraft engines, chemical machinery, suitable for non-lubrication and corrosion environment.

- High-end tools: scalpels, razor blades, industrial cutting tools, due to high hardness and sharpness retention.

- Die and wear parts: stamping die, plastic die template, ball screw, withstand high pressure and friction and wear.

- Aerospace: High temperature bearings (≤250 ° C), turbine components, using their high temperature dimensional stability.

- Medical instruments: Dental tools, surgical forceps, biocompatible and resistant to disinfectants.

CHEMICAL RATIO

95Cr18

APPLICATION TOOL STEEL GRADES

CHARACTERISTICS

Cutting Tools & Blades

- Surgical Instruments: Scalpels, razor blades, and dental tools due to high hardness (58-62 HRC) and corrosion resistance in sterilization environments1910.

- Industrial Blades: Precision cutting tools (e.g., drill bits, milling cutters, lathe tools) for machining carbon steels, alloy steels, and cast irons1411.

- Household Knives: High-end kitchen knives and scissors, leveraging sharpness retention and wear resistance38.

Bearing & Mechanical Components

- Aerospace Bearings: High-temperature bearings (≤250°C) in jet engines, utilizing thermal stability and corrosion resistance79.

- Automotive Parts: Transmission shafts, brake discs, and exhaust components requiring durability under cyclic stress19.

- Industrial Bearings: Roller bearings for machinery operating in corrosive or low-lubrication environments411.

Molds & Wear-Resistant Parts

- Plastic Molds: Cores and cavities for glass-fiber-reinforced polymers (e.g., PEEK, PPS) due to abrasion resistance19.

- Stamping Dies: Cold-forming dies for fasteners (bolts, rivets) and sheet metal processing tools48.

- Valves & Nozzles: Components in chemical processing equipment, resistant to weak acids and organic solvents311.

Specialty Applications

- Medical Devices: Orthopedic implants and surgical clamps, benefiting from biocompatibility and sterilizability710.

- Food Processing: Cutting blades and conveyor parts in hygienic environments39.

- Marine Hardware: Corrosion-resistant fasteners and pump components for saltwater exposure

CHEMICAL RATIO

Why Choos FCS Stainless Steel

Global market coverage

Shipping and customs clearance protection

Cooperate with international logistics companies to optimize shipping routes, avoid tariff risks, and ensure on-time delivery of orders

Multilingual services team

FCS tool steel has a complete work team, for example, we are equipped with English, German, Japanese and other multi-language customer service, which can reduce cross-border communication barriers.

Free samples available

FCS tool steel attaches importance to customer purchase experience, supports customers to apply for free sample testing, reduces the risk of purchasing decisions, and enhances the confidence of product experience.

Customized service

One-stop solution for non-standard sizes, special alloy ratios and surface treatments such as nitriding and coating.

After-sales guarantee

We have a professional after-sales team, can provide customers with high quality after-sales service. Provide warranty period, unconditional return of quality problems, establish long-term trust and cooperation.