For global service

Hot Work Tool Steel

workers

Company area/acres

Workshop area/SQM

Product Quantity

FCS Hot Work Tool Steel OEM Factory

Hot Work Tool Steel

Our Hot Work Tool Steel Products Include:

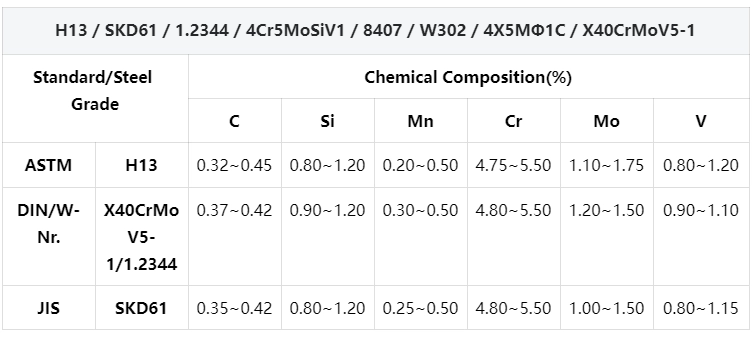

H13 / SKD61 / 1.2344 / 4Cr5MoSiV1 / 8407 / W302 / 4X5MΦ1C / X40CrMoV5-1

Ideal for die forging and hammer forging dies, our H13 steel ensures superior performance in high-temperature environments. It is perfect for aluminum alloy die casting, hot extrusion dies, and high-speed precision forging applications.

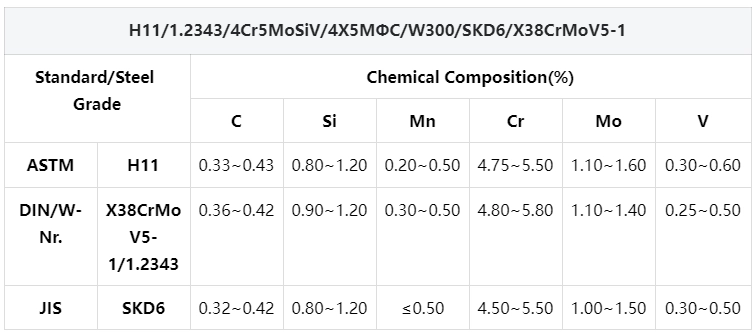

H11 / 1.2343 / 4Cr5MoSiV / 4X5MΦC / W300 / SKD6 / X38CrMoV5-1

This steel grade is engineered for high-speed hammer forging dies and excels in working with aluminum and magnesium alloy hot forging, providing exceptional durability and resistance to thermal fatigue.

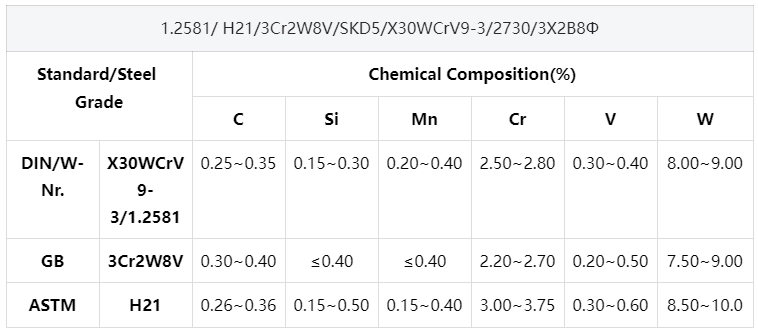

1.2581 / H21 / 3Cr2W8V / SKD5 / X30WCrV9-3 / 2730 / 3X2B8Φ

Known for its high hardness and thermal stability, this steel boasts remarkable wear resistance and hardenability. It is highly durable and machinable, making it a reliable choice for various hot work applications.

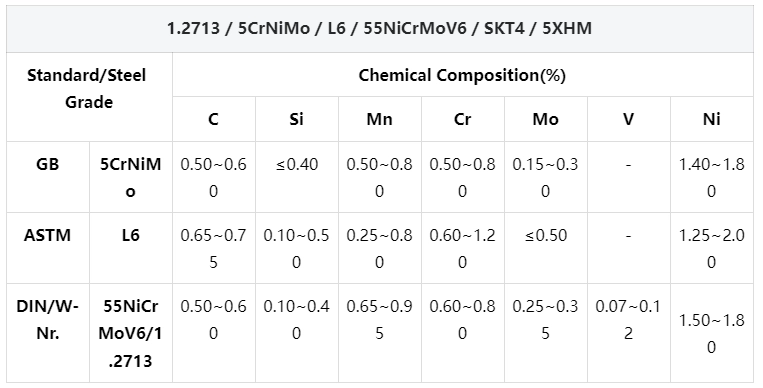

1.2713 / 5CrNiMo / L6 / 55NiCrMoV6 / SKT4 / 5XHM

This adaptable steel is perfect for large and medium-sized hammer forging dies and trimming dies. It excels in handling complex shapes and can withstand significant impact loads at lower working temperatures.

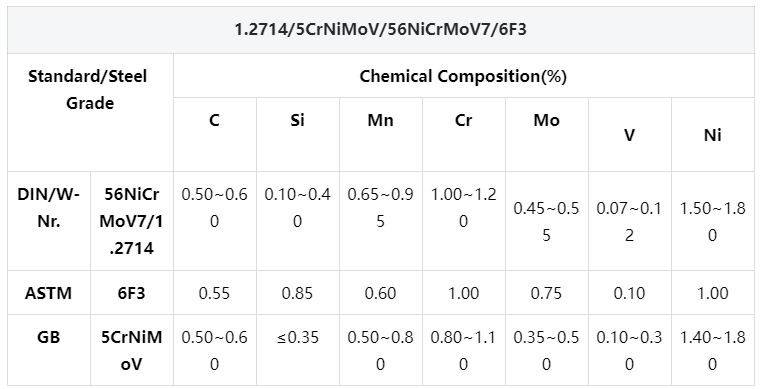

1.2714 / 5CrNiMoV / 56NiCrMoV7 / 6F3

Suitable for manufacturing a variety of large and medium-sized pressing molds and extrusion tools, this steel meets the high demands of thermoplastic plastic treatment and supports efficient mold base production.

Excellent properties of hot working tool steel

Superior High Temperature Strength

The use of advanced alloy formulations and heat treatment processes ensures that the steel maintains its high strength at high temperatures, effectively resisting deformation and cracking.

Outstanding wear resistance

Selection of high-quality raw materials, together with unique heat treatment technology, gives the steel excellent wear resistance, extends the service life of molds and reduces production costs.

Excellent thermal fatigue resistance

After special treatment, the steel has good thermal fatigue resistance and can withstand repeated heating and cooling to avoid premature mold failure.

A wide range of applications

It is widely used in die casting molds, hot forging molds, extrusion molds and other fields, and is an indispensable key material for manufacturing auto parts, aerospace parts, electronic and electrical components.

Hot working tool steel in line with multinational standards:

High packaging safety:

On time delivery:

Various Surface Options Available:

SIZE RANGE

- Round Bar:

- Flat bar:

1.2344

APPLICATION

H11

APPLICATION

Aluminum & Magnesium Alloy Hot Forging Dies: Superior thermal fatigue resistance for lightweight alloy shaping.Die-casting molds for EV battery housings and aircraft structural parts.

Extrusion Tools for Non-Ferrous Metals:Copper and titanium extrusion dies requiring prolonged heat exposure.

1.2581

TOOL STEEL GRADES

APPLICATION

1.2713

TOOL STEEL GRADES

APPLICATION

Heavy-Duty Hammer Forging Dies:Designed for large/medium-sized dies (e.g., automotive crankshafts, railway couplers) with complex geometries.Withstands extreme impact loads (≥1500 MPa) at low working temperatures (200–400°C).Maintains hardness 38-42 HRC under cyclic stress.

Low-Temperature Trimming Dies:Superior toughness (≥40 J/cm² Charpy impact) for high-precision trimming of thick steel plates. Shipbuilding, construction machinery (e.g., excavator bucket cutting edges).

Large Casting Molds for Heavy Machinery: Mining equipment molds (e.g., crusher jaws) requiring dimensional stability in sub-300°C environments.

1.2714

TOOL STEEL GRADES

APPLICATION

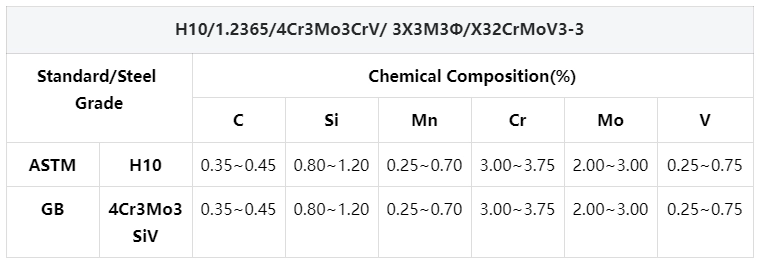

H10

TOOL STEEL GRADES

APPLICATION

H10 tool steel can be used to make male and female dies with high stress under high temperature but not subject to impact load, such as concave and convex dies, inserts, copper alloy extrusion dies, die-casting dies, such as reverse extrusion dies, and hot metal cutters under high temperature.

Why Choos FCS Hot WOrk Tool Steel

Customized service and fast response

Excellent cost performance

We have our own tool steel manufacturing factory, with a full set of high specification production equipment. Large-scale production reduces costs, the price is 15%-20% lower than that of similar Japanese products (such as SLD/SKD11), and the quality is benchmarked to international first-line brands.

Wide range of products

We have 110+ product categories in our daily production, and we can also provide product customization service. If you are interested in customized products, please contact us.

Free Technical Support

Multinational standard hot work tool steels

We can provide hot work tool steels of different national standards,such as U.S.A:ATSM/AISI,Russia:ГОСТ,Japen:JIS,German:DIN/W-Nr,Sweden:ASSAB,Austria:BOHLER,China:GB,EN,ISO ,etc.We can meet the needs of different customers, to provide you with one-stop procurement services.