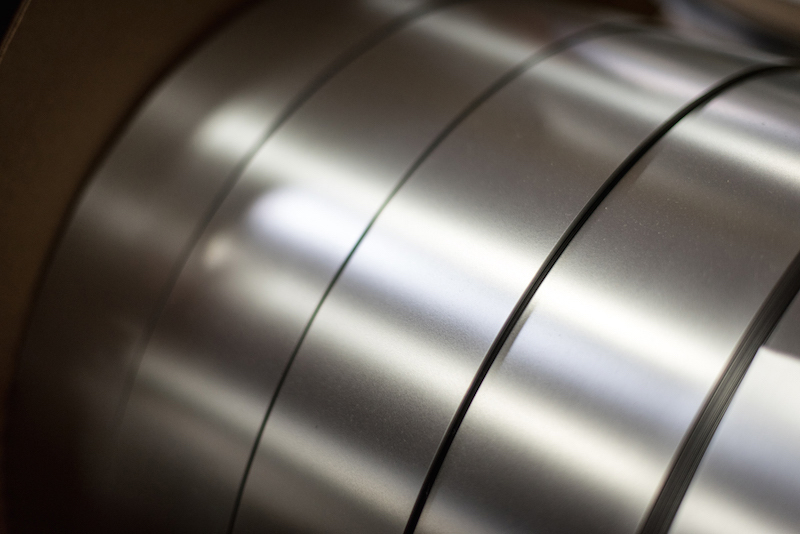

Stainless steel is everywhere – in kitchens and factories. It’s tough, reliable, and versatile. But with so many types and grades available, how do you choose the right one? I’ll help you make the best decision. Let’s take a closer look at stainless steel!

Understanding Stainless Steel

Stainless steel is a strong and versatile material used in many industries. It’s mainly made of iron, which makes up 50-72% of the alloy. Other elements like carbon, chromium, nickel, and molybdenum give stainless steel its special properties, such as resistance to rust, strength, and ability to be shaped.

Main Elements in Stainless Steel Composition

- Iron (Fe): The main part of the alloy, making up 50-72% of the composition.

- Carbon (C): Added in small amounts (0.03-0.08%) to strengthen the steel without losing flexibility.

- Chromium (Cr): Essential for preventing rust, it makes up at least 10.5% of the composition and creates a protective oxide layer.

- Nickel (Ni): Usually 8-12%, it boosts strength, flexibility, and resistance to acids.

- Manganese (Mn): Up to 2%, it improves toughness.

- Molybdenum (Mo): Added in small amounts (2-3%) to increase resistance to pitting and corrosion, especially in environments with high chloride content.

Properties of Stainless Steel

- Corrosion Resistance: Chromium forms a protective oxide layer that prevents rust.

- Mechanical Strength: Stainless steel, like grade 304, has a tensile strength of 520-720 MPa and can stretch at least 45%, thanks to the nickel and chromium.

- Physical Characteristics: Stainless steel has a density of 8,000 kg/m³ and melts at around 1450°C, making it durable at high temperatures.

- Weldability and Machinability: The presence of chromium and nickel makes welding easier by reducing the risk of cracking.

Types and Grades of Stainless Steel

Stainless steel comes in different types and grades, which are based on its chemical makeup and physical properties. The main types are austenitic, ferritic, martensitic, duplex, and precipitation hardening. Each type has its own benefits, including varying levels of corrosion resistance, strength, and formability.

Austenitic Stainless Steel

Austenitic stainless steels are recognized for their remarkable resistance to corrosion and their ability to be easily shaped. Typically, these steels exhibit non-magnetic properties, although they can become slightly magnetic under specific conditions. These stainless steels are essential in applications demanding superior corrosion protection, containing a minimum of 10.5% chromium and between 8-12% nickel, along with other alloying elements such as manganese, molybdenum, and nitrogen. Their tensile strength varies from 700 to 1300 N/mm², while their yield strength is generally lower, falling within the range of 200 to 300 N/mm².

- Examples:

- Type 301: Very ductile with great weldability. It has better wear resistance and fatigue strength than 304.

- Type 302: Similar to 304 but with slightly more strength due to extra carbon.

- Type 303: Contains sulfur and phosphorus for easier machining compared to 304.

- Type 304: Known as 18/8 stainless steel, the most common grade with 18% chromium and 8% nickel.

- Type 316: Provides better corrosion resistance due to the addition of molybdenum, making it ideal for harsh environment

Ferritic Stainless Steel

Ferritic stainless steels are magnetic, cost-effective, and commonly used in automotive and construction applications.It contains 10.5% to 27% chromium, with little to no nickel.

- Examples:

- Type 409: The most affordable grade, often used in car exhaust systems.

- Type 410: Martensitic but often grouped with ferritic steels. It is wear-resistant but less corrosion-resistant.

- Type 430: Offers good formability and is used for decorative purposes, though it has lower resistance to temperature and corrosion.

Martensitic Stainless Steel

Martensitic stainless steels are high strength and hard materials, mainly used in cutlery and surgical instruments.Contains 10.5–18% chromium and up to 1.2% carbon.

- Examples:

- Type 410: Wear-resistant but less corrosion-resistant, often used for general purposes.

- Type 420: Known as “surgical steel”, it polishes well and is used in high-end cutlery.

- Type 440: High-carbon steel with greater strength but lower weldability and formability.

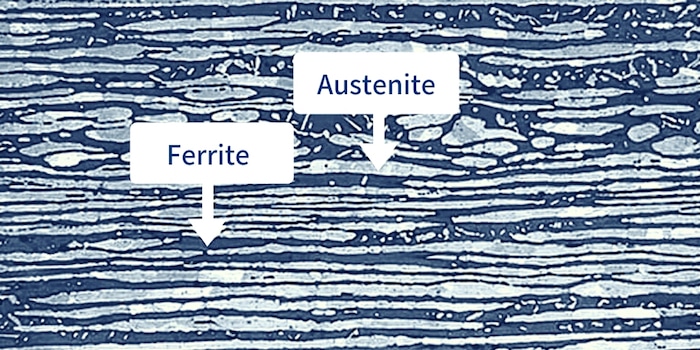

Duplex Stainless Steel

Duplex stainless steels are a versatile group of materials that effectively merge the advantageous properties of both austenitic and ferritic steels, resulting in notable strength alongside exceptional corrosion resistance. Featuring chromium content ranging from 18-28% and nickel between 4.5-8.5%, these alloys also benefit from enhancements like molybdenum and nitrogen. This unique composition grants them superior resistance to pitting and crevice corrosion compared to other stainless steel types, making them ideal for demanding applications in various industries.

- Examples:

- Type 2205: A widely used duplex stainless steel, known for its balance of strength and corrosion resistance, especially in chloride environments, often found in marine and chemical processing applications. ◦

- Type 2507: A super duplex stainless steel with higher chromium and molybdenum content, providing outstanding performance in very aggressive environments, such as offshore and heat exchanger applications.

- Type 2304: A lean duplex stainless steel that offers a cost-effective alternative with good corrosion resistance and strength for less demanding environments, commonly used in food processing and piping systems.

Precipitation Hardening Stainless Steel

Precipitation hardening stainless steels can be strengthened through heat treatment, offering a balanced combination of strength, corrosion resistance, and formability.

- Examples:

- 17-4PH: Used in aerospace and high-performance applications, offering both strength and corrosion resistance.

- 15-5PH: Known for good toughness and strength in demanding environments.

These different grades and types of stainless steel offer solutions for various applications, depending on the specific needs for corrosion resistance, strength, formability, and cost-efficiency.

Essential Features to Look for When Choosing Stainless Steel Cookware

When purchasing stainless steel cookware, focus on certain features to ensure its durability, performance, and long life.

1. Material Quality and Grade

The quality of stainless steel cookware significantly depends on the specific material grade used in its construction. When selecting cookware, it is advisable to prioritize options made from 18/10 or 18/8 grades, as they provide superior performance, durability, and resistance to corrosion.

- 18/10 Grade: This grade represents the best available option for stainless steel cookware, comprising 18% chromium and 10% nickel. This unique combination not only enhances its resistance to rust and oxidation but also ensures that the cookware retains its brilliant shine over time, making it an ideal choice for both home cooks and professional chefs. Moreover, 18/10 stainless steel has excellent heat distribution properties, which allows for even cooking and minimizes the risk of hot spots.

- 18/8 Grade: While slightly less robust than the 18/10 grade, the 18/8 stainless steel cookware still provides impressive performance. Composed of 18% chromium and 8% nickel, it offers good resistance to corrosion and wear, making it suitable for everyday use. This grade is a cost-effective alternative, striking a balance between durability and affordability, and is commonly found in various cookware essentials like pots, pans, and baking sheets, ensuring a reliable cooking experience.

2. The 300 Series Stainless Steel

The 300 Series Stainless Steel: The 300 series stainless steel, which includes the widely recognized 18/10 and 18/8 grades, is esteemed for its exceptional corrosion resistance, primarily attributable to its composition of nickel and chromium. This alloy not only enhances the material’s durability but also contributes to its aesthetic appeal with a shiny finish. Additionally, the 300 series is non-magnetic, making it an ideal choice for various applications where magnetic properties are undesirable. Due to these qualities, it has become a preferred material for the production of high-quality kitchenware, including pots and pans, which require both functional performance and an attractive appearance.

- Example: For instance, consider a professional chef who relies on durable cookware for daily cooking. By choosing 18/10 stainless steel pots, the chef benefits from excellent resistance to rust and staining, ensuring that the cookware remains in pristine condition even after extensive use. The non-magnetic property of these pots also means they are compatible with induction cooktops, further expanding their versatility in the kitchen.

3. Heat Conductivity

While stainless steel is known for its durability and resistance to corrosion, it is not an efficient conductor of heat on its own. To address this limitation, many manufacturers create cookware with core-clad designs that integrate other conductive metals, such as aluminum or copper. These materials enhance the cookware’s ability to distribute heat evenly, providing better cooking results and reducing hot spots. This combination allows for more precise temperature control, making it ideal for a wide range of culinary techniques.

Example:

- Core – Bottom Clad: Core – Bottom Clad: This design features a disc of a more conductive metal, such as aluminum or copper, placed strategically at the bottom of the cookware. This construction improves heat transfer directly at the base, resulting in faster and more uniform cooking.

- Core – Sandwich Cladding: In this design, a layer of a conductive metal is encapsulated by stainless steel on both sides. This method maximizes heat distribution across the entire cooking surface while maintaining the durability and non-reactivity of stainless steel, making it suitable for sautéing, simmering, and browning.

4. Induction Compatibility

Before purchasing cookware, it is essential to verify its compatibility with induction stoves. This can typically be done by examining the packaging for the official induction symbol, which resembles a series of concentric circles or the phrase “induction-compatible.” These indicators affirm that the cookware is designed to work with the electromagnetic technology of induction cooking, ensuring efficient heat transfer and optimal cooking performance.

- Example:When shopping for a new saucepan, you should look closely at the label. If you come across a saucepan that features the induction symbol, you can confidently purchase it, knowing it will work seamlessly on your induction cooktop. Conversely, if the label lacks this symbol, it may be an indication that the saucepan will not perform effectively, potentially leading to uneven heating or a complete lack of response on induction surfaces.

5. Weight and Construction

Weight and Construction: Heavier cookware often indicates superior construction quality, ensuring durability and consistent cooking performance. The increased weight allows it to retain heat efficiently, which is essential for evenly cooked meals, and it helps stabilize the cookware on the stove, reducing the risk of tipping over while in use. In general, high-quality cookware tends to have a heftier feel, providing a sense of reliability and sturdiness during cooking.

- Example: When comparing a lightweight aluminum frying pan to a heavier cast iron skillet, the cast iron skillet not only offers better heat retention but also remains more stable on the burner, allowing the chef to confidently sauté vegetables without the pan sliding around. This solid construction provides a more enjoyable cooking experience overall.

6. Corrosion Resistance

When selecting cookware for preparing salty or acidic dishes, 316 stainless steel stands out as an excellent choice due to its unique composition, which includes 2% molybdenum. This additional element significantly enhances the material’s resistance to corrosive substances like acids, alkalis, and chlorides. As a result, 316 stainless steel cookware is especially suitable for cooking with reactive ingredients such as tomatoes, citrus fruits, or seafood. The robust construction ensures that the cookware will maintain its integrity and not impart any metallic flavors to delicate dishes, allowing you to prepare your meals with confidence and longevity in mind.

- Example: If you’re making a classic tomato sauce that includes fresh tomatoes and red wine, using 316 stainless steel cookware will prevent any metallic taste from leaching into the sauce. This way, the natural flavors of the tomatoes can shine through without interference from the cookware itself, highlighting the quality of your ingredients and resulting in a delicious end product.

7. Coating and Layering

Cookware with multiple layers (e.g., 3, 5, or 7 layers) provides better heat retention and more even cooking. The core layers often include aluminum or copper to enhance heat conductivity. This multi-layer construction minimizes hot spots and reduces the risk of burning or unevenly cooked food, ensuring a consistent cooking experience. High-quality cookware often features non-stick coatings as well, which not only make food release easy but also facilitate effortless cleanup.

- Example: A popular example of this kind of cookware is a 5-ply stainless steel pan that utilizes a copper core sandwiched between layers of aluminum and stainless steel. This design allows the pan to heat up quickly and maintain a steady temperature, making it ideal for tasks like searing meats or simmering sauces. The stainless-steel exterior provides durability and resistance to scratching, while the aluminum and copper layers ensure optimal heat distribution, resulting in perfectly cooked dishes without the risk of burning.

8. Austenitic Stainless Steel

Austenitic stainless steel grades, such as 18/10 and 18/8, are favored for culinary implements due to their outstanding durability and resistance to rust. These alloys predominantly maintain a non-magnetic state, though they may display slight magnetism if subjected to deformation or hard work. This behavior is mainly due to the high nickel content present in these materials, contributing to their increased ductility and strength. When choosing stainless steel cookware, it’s important to recognize the specific properties these alloys possess, as they can significantly influence cooking performance and complement your kitchen’s design aesthetic.

- Example: When preparing a gourmet dish that requires precise temperature control, a high-quality 18/10 stainless steel saucepan would be ideal. Its excellent heat retention and non-reactive surface ensure that the delicate flavors of the ingredients are preserved, allowing for an impressive culinary presentation.

summary

When choosing stainless steel, you should consider durability, corrosion resistance, and ease of use. Whether you’re buying cookware or industrial tools, knowing the different types and grades helps you get the best performance. With the right choice, stainless steel offers long-lasting reliability and practical use in daily life.