I’ve often noticed some tools can handle tough use without damage, while others focus on weight and rust resistance. It all comes down to what they’re made of – titanium and tool steel. These two metals are top choices for everything from airplane parts to workshop tools. Each metal works best in different situations. How do you pick the right material for what you need? In my experience, beyond just looking at strength or price, many people miss one key factor…

Overview of Titanium and Tool Steel

Titanium: The Light and Strong Metal

As I hold titanium in my hand, I’m mesmerized by this silver-white marvel of nature. I’ve grown to love this element (Ti, atomic number 22) and its amazing contrasts. It weighs just 4.51 g/cm³, feeling 40% lighter than steel in my palms, but it still resists forces that would bend other metals. Titanium shows its strength through a slim, light form. I’ve worked with many metals, and I find that nothing compares to titanium’s strength-to-weight ratio. To me, it’s like seeing the power of an eagle packed into the tiny body of a hummingbird.

Titanium melts at a high temperature (1668°C), so it works well in hot settings. I’m amazed by how it resists rust and corrosion, making it perfect for harsh places. The downside? It’s hard to cut and shape because it doesn’t conduct heat well and reacts with other materials. Titanium costs between $35 and $50 per kg, which makes it a high-end metal.

Tool Steel: Tough and Lasting

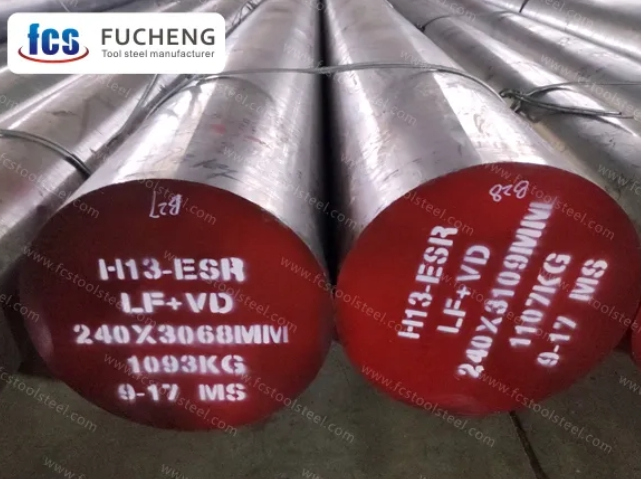

Tool steel is a carbon alloy steel made for tools and dies used in factories. It contains 0.6% to 1.5% carbon, giving it great hardness and wear resistance. I’ve seen how tool steel keeps its shape and edge during tough jobs like fast cutting and heavy hits.

At 7.8–8 g/cm³, tool steel weighs more than titanium but has higher hardness scores (Brinell: 120–321). Its strength ranges from 860 MPa to 1980 MPa, based on the grade, making it good for high-stress uses. It has some rust resistance, and coatings can help it last longer. I find that tool steel is easier to work with than titanium. It’s also much cheaper, costing between $1.50 and $6 per kg.

Composition and Types

| Type | Composition | Properties | Applications |

|---|---|---|---|

| Pure Titanium | |||

| Grade 1 | 0.18% wt oxygen | Lowest strength, highest ductility | Plating, pipes, medical tools |

| Grade 2 | 0.25% wt oxygen | Higher strength than Grade 1 | Power plants, saltwater systems |

| Grade 3 | 0.35% wt oxygen | Stronger than Grade 2 | Cold storage tanks, marine equipment |

| Grade 4 | 0.4% wt oxygen | Highest strength in pure titanium | Medical implants, aerospace components |

| Titanium Alloys | |||

| Alpha Alloys | Mixed with aluminum | Excellent corrosion resistance, high-temperature stability | Aircraft structures, chemical processing equipment |

| Beta Alloys | Mixed with vanadium/molybdenum | High strength with good formability | Welding applications, high-stress environments |

| Alpha-Beta Alloys | Combined alpha/beta properties | Balanced strength and ductility | Aerospace (Grade 5/Ti-6Al-4V), medical implants, automotive parts |

| Tool Steel | |||

| Water-Hardened (W-grade) | Low cost, low heat resistance | Basic cutting tools | Knives, chisels, punches |

| Cold-Work Tool Steel | High carbon/chromium | Wear resistance, high hardness | Dies, punches, cutting tools |

| Hot-Work Tool Steel (H-grade) | High heat resistance | Maintains hardness at elevated temperatures | Forging dies, extrusion tools |

| High-Speed Steel (HSS) | Tungsten/molybdenum additions | Retains hardness at high speeds | Drill bits, saw blades, milling cutters |

| Special-Purpose Tool Steel | Customized compositions | Tailored for specific needs (e.g., shock resistance, corrosion resistance) | Surgical instruments, high-precision tools, marine applications |

Mechanical Properties

Strength and Resistance

Titanium has tensile strength from 140 MPa (pure) to 1250 MPa (in alloys like Ti-6Al-4V). It has great fatigue resistance, with strengths of 155-205 MPa. I’m impressed by its strength-to-weight ratio, thanks to its low 4.51 g/cm³ density.Tool steel offers much higher tensile strength, from 860 MPa to 1980 MPa, based on grade and heat treatment. It keeps high fatigue strength during repeated loads, even in tough settings.

Elasticity and Rigidity

I’ve noticed that titanium bends like a small tree in the wind because of its lower elastic modulus (115 GPa). It gives way under pressure. I’ve found that for projects needing stiff materials, I must use other options. Titanium’s bendable nature, though useful in some cases, doesn’t work well when I need something rigid.

From what I’ve seen, tool steel is much firmer with its 200 GPa elastic modulus. I like how it stays strong under forces that bend titanium. When my projects need a material that won’t move under heavy stress, I choose tool steel. It has always worked well for me.

Hardness and Toughness

I’ve worked with many materials over time and grown to love titanium. It’s not as hard as tool steel—measuring around 70 on the Brinell scale—but I’m impressed by how well it resists cracks. Titanium reminds me of a tough fighter who can bend without breaking. It offers resistance between 28 and 108 MPa√m, depending on the alloy type. I can sense its toughness whenever I hold a piece.

Tool steel feels like a strong fortress in my shop. With hardness ratings of 24-62 HRC, it stands as the strongest metal I work with. I love using S7 and H13 types, which I find very strong. I enjoy watching these steels resist chips, cracks, and stress. They remind me of old trees that stand through storms without falling.

Weight and Density

I’m always amazed at how titanium feels almost ethereal in my hands at just 4.51 g/cm³. I find this unusual lightness gives it a clear edge in situations where weight counts. When I work with titanium, I feel its great strength despite being light. It reminds me of having lion-like power in a cat-sized package.

Tool steel, on the other hand, carries a substantial presence at 7.8–8 g/cm³. I’ve found that this weight creates a stiffness I can feel when I hold it. I think this extra mass makes it ideal for high-stress projects. It stays firm against strong forces, much like a sturdy oak tree.

Specialized Resistance

Titanium resists creep well at medium temps. It doesn’t do as well in very high heat. Its cracks grow slowly under stress. This makes it last longer when used often.

Tool steel has high crush strength. It stands up to strong physical stress. It also shows great wear resistance in rough conditions.

Choosing Between Titanium and Tool Steel

I find that several key factors matter when picking between titanium and tool steel. These include weight, strength, hardness, rust resistance, wear, and cost. Here’s my guide to help you choose:

Weight Considerations

I love titanium’s light 4.5 g/cm³ density—it feels like the ideal partner for my designs. From my work with lightweight materials, this metal fits into many uses with ease. I see its value in aircraft, small electronics that fit well in hand, and sports gear that feels almost weightless to athletes.

Tool Steel weighs much more at 7.75–8.05 g/cm³. When I use it, I feel its weight strain my arms—a clear sign it’s wrong for weight-critical projects. I’ve failed with many designs using this heavy material. I recommend avoiding it for projects where weight affects success.

Strength and Hardness

Tool Steel is very hard and great for tough jobs like metal-forming dies and cutting tools. It works well under pressure in factories and heavy-duty jobs.

Example: Hard tool steel has strong tensile strength for mining tools and factory machines.

Titanium has amazing strength for its weight, but isn’t as hard as tool steel. It resists bending in medical parts and aircraft structures.

Example: Grade 5 titanium offers 890–950 MPa tensile strength, used in planes and boats.

Corrosion Resistance

Titanium has an oxide layer. So it can prevent rust very well. I recommend it for salt water uses, like in ships or chemical factories.Example: Titanium pipes resist pitting in seawater and last much longer.Some stainless steel types resist rust, but not as well as titanium in harsh conditions.

Wear Resistance

Tool Steel can withstand scraping and rubbing in rough places like mines and heavy machines. Good for drill bits and conveyor parts.

Titanium is tough but wears down faster. So I don’t suggest it for rough, gritty uses.

Cost Comparison

Tool Steel is low cost , great for budget projects and mass production. I find it practical for basic tools and dies.

Example: Works well for small factories due to low cost.

Titanium is much more costly—up to 30 times more than stainless steel—but lasts longer with less upkeep.

Example: Best for planes’ engines where saving weight and fighting rust justify the high price.

Key Guidelines

I suggest titanium for projects needing light weight and rust resistance, like in planes, boats, or medical tools.

I recommend tool steel when you need hardness, wear resistance, and want to save money, such as in making tools or heavy machines.

Summary of Strengths and Limitations

Strengths of Titanium

| Strength | Description |

|---|---|

| Lightweight & High Strength-to-Weight Ratio | Density: 4.51 g/cm³; Tensile strength: 350–1200 MPa. |

| Biocompatibility | Non-toxic and non-reactive with human tissues, ideal for medical implants. |

| Corrosion Resistance | Resists rust and degradation in extreme environments (e.g., saltwater, aircraft). |

| Fatigue Resistance | Withstands repeated stress cycles over long periods. |

| Versatility | Used in aerospace, marine, and medical industries. |

Limitations of Titanium

| Limitation | Description |

|---|---|

| High Cost | $35–50 per kilogram (significantly more expensive than tool steel). |

| Machining Difficulty | 30% harder to cut than stainless steel, requiring specialized tools. |

| Heat Sensitivity | Poor thermal conductivity increases risk of damage during machining. |

| Lower Rigidity & Moderate Hardness | Young’s modulus: 116 GPa; Brinell hardness: ~70 (less stiff than tool steel). |

Strengths of Tool Steel

| Strength | Description |

|---|---|

| Hardness & Wear Resistance | Brinell hardness >121; retains edge at high temperatures (~600°C). |

| Machinability | Easier to shape than titanium, reducing manufacturing costs. |

| Affordability | $4–6 per kilogram (cost-effective for tooling). |

| High Tensile Strength | Up to 3000 MPa, suitable for heavy-duty applications. |

| Specialized Applications | Used for cutting tools, dies, punches, and high-precision machinery. |

Limitations of Tool Steel

| Limitation | Description |

|---|---|

| Weight | Density: 7.8–8.0 g/cm³ (much heavier than titanium). |

| Susceptibility to Rust | Prone to corrosion unless alloyed with chromium (e.g., stainless steel). |

| Lower Flexibility | Young’s modulus: ~200 GPa (less ductile than some alternatives). |

| Limited Versatility | Primarily used for toolmaking, restricting use in broader industries. |

summary

I compared titanium and tool steel and learned that picking the right metal means matching it to what you need. Titanium works best for light items that must resist rust. Tool steel is better when you need something hard and less costly. This knowledge has changed how I plan my projects. I now make better choices that match my needs for how well it works, how long it lasts, and what I can spend. The best material isn’t always the priciest or toughest—it’s the one that fits what you’re trying to do.