When choosing the right tool steel for your project, you may wonder which one offers the best balance of durability, corrosion resistance, and performance. A popular option is 1.2083 tool steel, commonly used in industries like mold making and surgical tools. How does it compare to other tool steels? What should you consider when selecting a supplier? There is one important factor you might be missing.

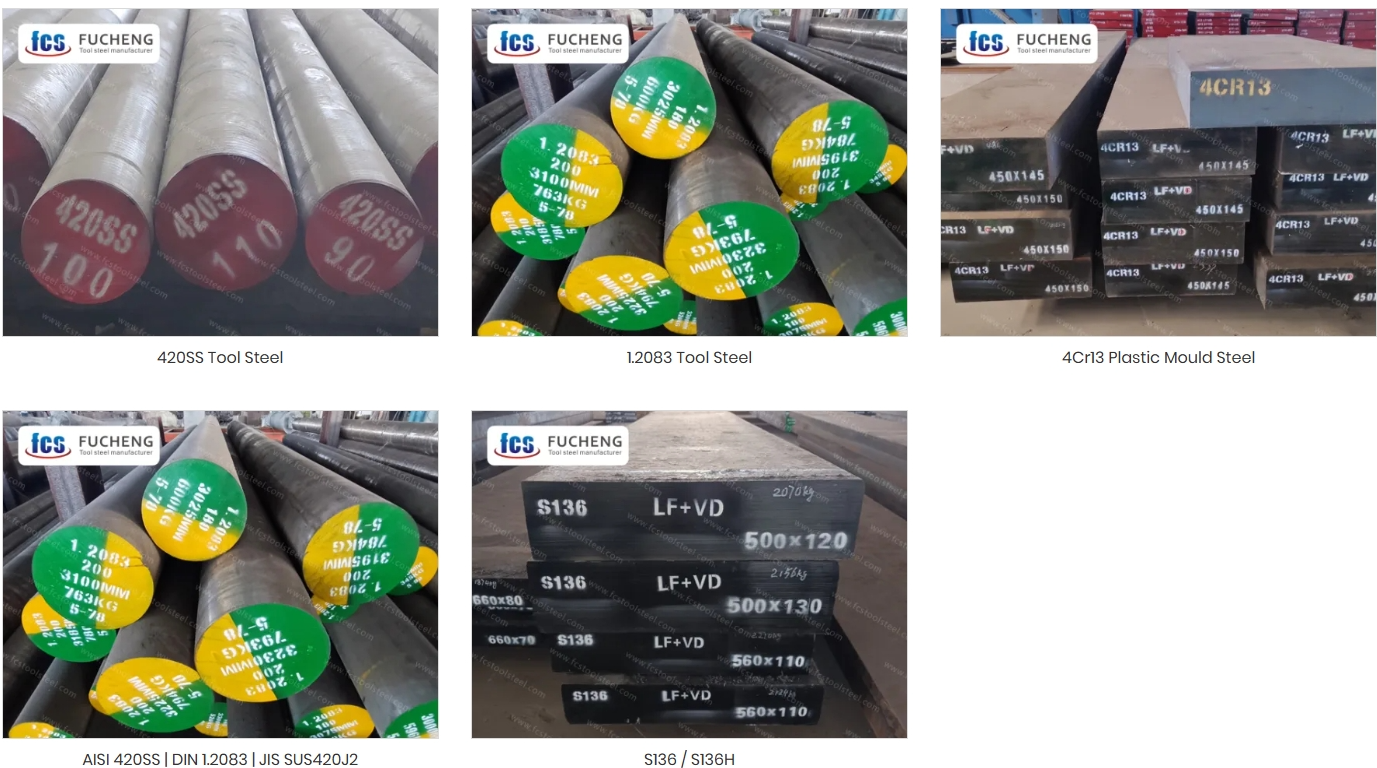

Equivalent Grades of 1.2083 Tool Steel

1.2083 tool steel is known for its strong corrosion resistance and wear resistance. It is used in industries like mold making and tooling. Here are the equivalent grades of 1.2083 tool steel from various countries and standards:

| Country/Standard | Grade | Other Common Names | Leading Manufacturers |

|---|---|---|---|

| USA (AISI/ASTM) | 420SS | – | Böhler, Uddeholm, Hitachi Metals |

| Germany (DIN) | X40Cr13 / 1.2083 | Böhler M310, Uddeholm Stavax ESR | Böhler, Uddeholm, Hitachi Metals |

| Japan (JIS) | SUS420J2 | Assab 8407 Supreme | Hitachi Metals, Assab |

| China (GB) | 4Cr13 | – | Schmolz + Bickenbach, Voestalpine |

| UK (BS) | 420S45 | – | Crucible Industries |

| France (AFNOR) | Z40C14 | – | – |

| Italy (UNI) | X40Cr14 | – | – |

| Sweden (SS) | S136 | – | Assab |

| Russia (GOST) | 40X13 | – | – |

1.2083 equivalent tool steel chemical element comparison

1.2083 tool steel is incredibly durable. It has a shiny, polished finish. You can rely on it when you need precision and strength—whether you’re making plastic molds, fine-tuning surgical tools, or perfecting a knife set. This steel is built to last, with great resilience over time. Compared to other grades of steel worldwide, it stands out for its versatility and strength.

Comparison of chemical elements

| Country/Standard | Equivalent Grade | C (%) | Cr (%) | Mo (%) | Mn (%) | Si (%) | V (%) | S (%) | P (%) |

|---|---|---|---|---|---|---|---|---|---|

| Germany (DIN) | X40Cr13 /1.2083 | 0.38–0.45 | 12.5–13.5 | 0.15–0.25 | ≤1.00 | ≤1.00 | 0.10–0.30 | ≤0.015 | ≤0.030 |

| USA (AISI) | 420SS | 0.38–0.45 | 12.0–14.0 | 0.20–0.40 | ≤1.00 | ≤1.00 | ≤0.50 | ≤0.030 | ≤0.030 |

| Japan (JIS) | SUS420J2 | 0.26–0.40 | 12.0–14.0 | ≤0.50 | ≤1.00 | ≤1.00 | – | ≤0.030 | ≤0.040 |

| China (GB) | 4Cr13 | 0.36–0.45 | 12.0–14.0 | ≤0.50 | ≤1.00 | ≤1.00 | – | ≤0.030 | ≤0.035 |

| Sweden (SS) | S136 | 0.38–0.45 | 12.5–13.5 | 0.15–0.25 | ≤1.00 | ≤1.00 | 0.10–0.30 | ≤0.015 | ≤0.025 |

Application Comparison of 1.2083 Tool Steel and Its Equivalents

I compare 1.2083 tool steel to other grades, I see it like choosing the right tool for a task. Each type has its strengths. The choice depends on the environment and industry needs. It’s about finding the best fit for the job.

| Grade/Property | Primary Applications | Suitability | Key Limitations |

|---|---|---|---|

| 1.2083 Tool Steel (DIN) | – Plastic injection molds (PVC/corrosive plastics) – Medical tools – Food-grade components |

High-polish surfaces; resistant to acidic environments | Less cost-effective in regions with limited availability |

| AISI 420 Modified | – Corrosion-resistant molds – Surgical instruments – Marine components |

Enhanced performance in harsh chemical environments (due to Mo) | Slightly inferior polishability vs. 1.2083 |

| SUS420J2 (JIS) | – General-purpose molds – Cutlery – Low-corrosion industrial parts |

Cost-effective for mild corrosive environments; good toughness | Unsuitable for prolonged strong acid exposure |

| 4Cr13 (GB) | – Plastic molds – Kitchenware – Low/medium-stress tools |

Widely available in Asia; bulk production-friendly | Lower wear resistance in high-stress applications |

| SS 2083 (SS) | – Precision molds – Optical lens tooling – Decorative parts |

Matches 1.2083 performance; preferred in Europe | Higher cost outside Europe |

Comparison to Other Tool Steels

| Property | 1.2083 vs. Other Grades |

|---|---|

| Corrosion Resistance | Superior to D2/A2 tool steels |

| Wear Resistance | Inferior to D2 tool steel |

| Machinability | Easier to machine than D2 in annealed state |

| Cost | More expensive than 1.2344 (H13) hot work tool steel |

Top Tool Steel Manufacturers Recommendations

Looking for a reliable tool steel manufacturer, I suggest choosing companies that make high-quality products and have a good reputation. I’ve noticed that companies that combine craftsmanship with expertise often stand out. These manufacturers are known for their precision and dedication. They are trusted around the world for delivering steel that lasts. Their strong support networks give me confidence, knowing help is always available when I need it.

| Company Name | Headquarters Country | Key Products & Strengths |

|---|---|---|

| FCS Tool Steel | China | China tool steel/die steel producer with more than 18 years of experience, with a strong market share. |

| Proterial, Ltd. (Hitachi Metals) | Japan | Top Japanese manufacturer of high-strength, durable tool steels with advanced technologies. |

| Daido Steel Co., Ltd. | Japan | Renowned for precision tool steels and cutting-edge manufacturing processes. |

| Tremblay Tool Steels, LLC | USA (Ohio) | Supplier of tool steels/carbon alloys since 1987, offering tailored solutions for tooling. |

| Voestalpine High Performance Metals | Austria | Global leader in tool steels and specialty metals, known for reliability and precision. |

| Uddeholm USA | USA (subsidiary of Sweden’s Uddeholm) | High-quality tool steels for demanding applications, part of a Swedish heritage. |

| Ellwood Specialty Steel | USA | Fully integrated producer of tool steels for molds, dies, and precision tooling. |

| Böhler-Uddeholm | Austria | Premium tool steels and specialty forgings, combining Austrian and Swedish expertise. |

| Schmolz + Bickenbach | Germany | German tool steel manufacturer since 1919, offering a wide range of high-performance grades. |

| Swiss Steel Group | Switzerland | Leading global producer of high-performance tool steels and specialty alloys. |

Factors to Consider When Choosing a Tool Steel Supplier

I choose a tool steel supplier.I look for high-quality materials, fair prices, and reliable service. It’s like finding a partner who delivers quality and ensures I’m always supported. It’s important to me that I get the right product and that I can count on them when I need it most.Knowing they’ll always be there for me.

| Factor | Key Considerations |

|---|---|

| Product Range & Fabrication | – Broad selection of tool steel grades – Cutting, heat treatment, machining services – One-stop shop for streamlined ordering |

| Quality Assurance | – ISO 9001 certification – Material test certificates – Transparent quality control procedures |

| Technical Expertise | – Skilled metallurgists/engineers for grade selection – Support for design optimization and troubleshooting |

| Reputation & Track Record | – Customer reviews and case studies – History of reliable quality and service |

| Inventory & Lead Times | – Stock availability of common grades – Urgent order handling – Supply chain reliability |

| Pricing & Payment Terms | – Competitive pricing vs. quality balance – Bulk discounts and flexible payment options |

| Geographic Location | – Proximity for reduced shipping costs – Distribution network efficiency |

| Customer Service | – Responsive communication – Knowledgeable staff – Adaptability to special requests |

| Value-Added Services | – Heat treatment, machining, or testing included – Outsourcing reduction benefits |

| Sustainability Practices | – Environmental policies and recycling programs – Sustainable sourcing alignment |

summary

Choosing the right tool steel is all about finding the best material for your needs. Whether it’s a precision mold, a surgical instrument or a heavy component, knowing the material options available can make a big difference. I recommend that you choose a reliable supplier with quality assurance and expertise. With the right material, you’re not just making tools, you’re laying the foundation for lasting performance and success on every project.