Picking between D2 tool steel and A2 tool steels can be tough. Both work well for tools, but they perform differently. D2 lasts longer against abrasion. A2 handles impacts better and cuts more easily during manufacturing. I suggest focusing on this key point people usually miss: their core strength comes from different chemical balances. From my experience, this difference matters more than people realize when selecting materials.

Chemical Composition

D2 and A2 tool steels are like two distinct personalities, each with their own unique chemical makeup. These differences shape how they behave under pressure. And what they bring to the table in terms of durability and strength.These differences make D2 more wear-resistant and harder. A2 is tougher and easier to machine. From my experience, I recommend D2 for cutting tools and A2 for parts needing impact resistance.

| Type of tool steel | Carbon | Chromium | Molybdenum | Vanadium | Manganese | Silicon |

|---|---|---|---|---|---|---|

| D2 tool steel | 1.55% | 12% | 0.80% | 0.90% | 0.35% | 0.25% |

| A2 tool steel | 1.00% | 5.0% | 1.00% | 0.25% | 0.75% | 0.30% |

Hardness

D2 tool steel typically achieves a higher hardness range compared to A2 tool steel. The difference in hardness is primarily due to the chemical composition of each steel. D2 has a higher carbon content (1.4-1.6% vs 1.0% in A2) and a higher chromium content (11-13% vs 5% in A2).

| Comparison Items | D2 Tool Steel | A2 Tool Steel |

|---|---|---|

| Typical Working Hardness Ranges | 60 – 62 HRC | 58 – 60 HRC |

| Hardness Retention at Elevated Temperatures | Maintains hardness up to ~900°F | Begins to soften above ~800°F |

| Hardness vs. Toughness Trade-off | Higher hardness but reduced toughness | Better impact and crack resistance at similar hardness levels |

| Machinability in Annealed State | 65% of 1% carbon steel | 85% of 1% carbon steel |

Wear Resistance

Comparing D2 tool steel and A2 tool steel. D2 stands out with its superior hardness, like a rock-solid shield built to withstand anything.These powerful elements work together during heat treatment, forming more carbides that give D2 its harder edge. It’s like D2 has an extra layer of armor, ready to tackle tougher tasks with ease.For applications that require a mix of wear resistance and impact strength, A2 may be the better choice despite its lower wear resistance.

| Comparison Items | D2 Tool Steel | A2 Tool Steel |

|---|---|---|

| Key Differences in Wear Resistance | Offers exceptional edge retention and resists abrasive wear better, making it ideal for applications that demand high durability. | Provides moderate wear resistance, making it suitable for applications with less severe abrasive conditions. |

| Preferred for high-volume production runs where tool longevity is crucial. | Strikes a balance between wear resistance and toughness, making it ideal for tasks requiring both durability and impact resistance. | |

| Comparative Wear Resistance Rating | 8-9/10 | 6-7/10 |

| Examples of Applications | Slitter blades, industrial shear blades, cold forming dies | Punches, stamping dies, thread rolling dies |

Toughness

For durability, A2 tool steel outperforms D2 tool steel. A2 acts like a tough protector for tools. It resists shocks well and handles sudden impacts. I’ve found it can take heavy hits and keep working, which makes it ideal for high-pressure jobs. A2 tool steel scores 40-45 ft-lbs in toughness tests. D2 tool steel only reaches 15-25 ft-lbs, showing it struggles more under stress. If you need dependable strength, I recommend A2 tool steel.

This significant difference in toughness makes A2 tool steel more suitable for tasks like: 1) Punches and dies exposed to shock loads.2) Forming dies for thicker materials. 3)Applications that require good impact resistance

On the other hand, D2 tool steel is more brittle, especially at higher hardness levels. Its reduced toughness is a trade-off for its superior wear resistance and excellent edge retention. D2 tool steel is commonly used for: 1) Wear-resistant cutting tools.2) Slitting and shearing blades.3)Applications where edge retention is more critical than toughness.

At higher hardness levels, the toughness gap between A2 tool steel and D2 tool steel becomes even more evident. For instance, at 60 HRC, A2 tool steel maintains significantly better impact resistance than D2 tool steel, highlighting its toughness advantage in demanding conditions.

Machinability

Working with D2 tool steel.You’ll find that its machinability can feel like pushing through a dense forest—tough and slow-going. With a machinability rating of just 27%, it’s no walk in the park. In contrast, A2 tool steel is like a well-paved road with a machinability rating of 42%. It’s much smoother to work with, allowing your tools to glide through the material with ease.

| Comparison Items | D2 Tool Steel | A2 Tool Steel |

|---|---|---|

| Steel Type | High-carbon, high-chromium cold work steel | Air-hardening tool steel |

| Machinability | Difficult to machine due to high hardness, requires carbide tooling and slower speeds | Good machinability in annealed state, can use conventional methods |

| Recommended Turning Speed | 100 – 135 m/min | 155 – 210 m/min |

| Recommended Milling Speed | 60 – 85 m/min | 95 – 130 m/min |

| Recommended Drilling Speed | 40 – 55 m/min | 60 – 85 m/min |

| Special Machining Requirements | Specialized techniques (e.g., EDM, abrasive machining) needed, especially in hardened state. Use copious coolant or machine dry with light cuts and high speeds. | More forgiving, can be machined with standard techniques and parameters |

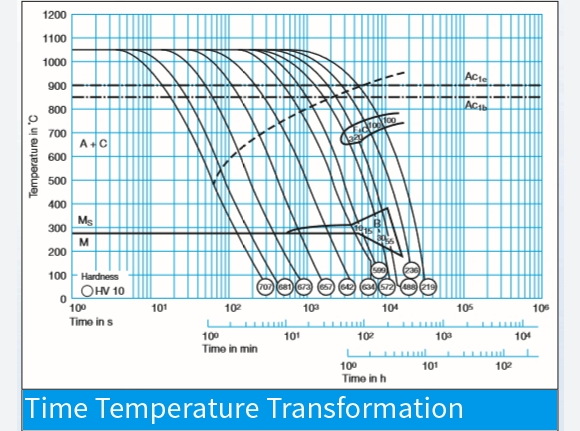

Heat Treatment

The way D2 tool steel and A2 tool steels are heat-treated is like tailoring a suit to fit their unique needs.Each method unlocks specific strengths. Making one perfect for certain tasks and the other for entirely different ones.

| Comparison Items | D2 Tool Steel | A2 Tool Steel |

|---|---|---|

| Austenitizing Temperatures | 1800 – 1875°F (982 – 1024°C) | 1725 – 1750°F (941 – 954°C) |

| Quenching | Generally requires oil quenching or air quenching with forced air for optimal properties | Can be air quenched |

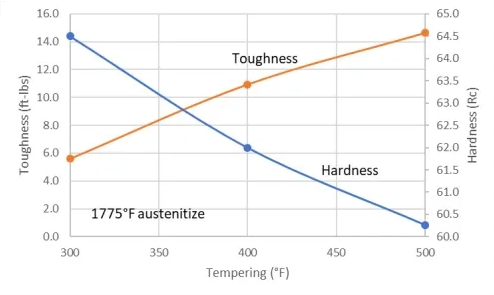

| Tempering | Tempered at 400 – 600°F (204 – 316°C) for the best properties | Tempered at 300 – 500°F (149 – 260°C) to achieve maximum hardness |

| Hardness Achieved | Can achieve a hardness range of 60 – 64 HRC after proper heat treatment | Can achieve a hardness range of 58 – 62 HRC |

| Dimensional Stability | More prone to size changes during heat treatment | Offers better dimensional stability during heat treatment |

| Decarburization Risk | More susceptible to decarburization due to higher carbon content; requires more careful atmosphere control during heat treatment | Less susceptible to decarburization compared to D2 |

| Stress Relief | Stress relieved at 950 – 1050°F (510 – 566°C) | Stress relieved at 1050 – 1250°F (566 – 677°C) |

| Annealing | Requires higher annealing temperatures of 1600 – 1650°F (871 – 899°C) | Annealed at 1550 – 1600°F (843 – 871°C) |

Edge Retention

D2 tool steel has better edge protection. This is mainly due to its higher carbon content (1.5-1.8% vs. 1.0%) and chromium content (11-13% vs. 4.75-5.5%). These differences lead to the formation of more carbides during heat treatment, improving wear resistance and edge holding.

| Comparison Items | D2 Tool Steel | A2 Tool Steel |

|---|---|---|

| Edge Retention | Excellent, maintains sharpness for longer | Good, but dulls faster than D2 |

| Typical Edge Retention Test Results (CATRA testing) | 150 – 200 cuts | 100 – 150 cuts |

| Factors for Edge Retention | Higher volume of chromium carbides Greater hardness (58-62 HRC) More abrasion-resistant microstructure |

|

| Trade-offs | Better edge retention, reduced toughness, more prone to chipping | Easier to sharpen, less prone to chipping, lower edge retention |

| Practical Implications | Ideal for tools needing extended cutting without frequent resharpening | Preferred for impact-resistant tools or when easy maintenance is important |

Applications

D2 and A2 tool steels are both widely used, but their applications differ due to their distinct properties.D2 excels in high-wear applications where edge retention is critical.A2 is more suitable for applications that require toughness and improved machinability, especially where tools need more frequent resharpening or modification.D2 is favored for longer production runs and dealing with abrasive materials.A2 is chosen when a balance of wear resistance and toughness is required for general-purpose tooling.

| Comparison Items | D2 Tool Steel | A2 Tool Steel |

|---|---|---|

| Applications | Cutting tools Forming tools Wear-resistant parts Industrial knives Plastic molds for abrasive polymers |

Punches and dies for longer production runs Forming and bending tools Blanking and trimming tools Gauges and measuring tools Cold heading tools Burnishing tools Lamination dies Coining dies |

D2 tool steel is typically preferred when extreme wear resistance is essential, while A2 is better for applications requiring a balance of toughness and wear resistance, making it versatile for a broader range of tools.

Cost

Comparing the costs of A2 and D2 tool steels, A2 is generally the more economical option. This is primarily due to its lower alloy content, which makes it cheaper to produce. Here are the key points regarding the cost difference.A2 typically costs 20-30% less than D2 for similar sizes and forms.The cost gap becomes more noticeable for larger cross-sections and longer lengths.D2’s higher chromium and carbon content results in higher raw material and processing costs.A2 is more readily available, which helps reduce lead times and costs.

| Comparison Items | D2 Tool Steel | A2 Tool Steel |

|---|---|---|

| Typical Price Ranges | $7 – 20 per pound | $5 – 15 per pound |

| Example Pricing (1″ x 1″ x 36″ bar) | $209.62 | $60.94 |

| Pricing for Larger Sizes (2″ x 2″ x 12″ flat) | ~$180 | ~$120 |

While D2 tool steel is known for superior wear resistance, A2 offers a more cost-effective solution for applications where extreme abrasion resistance isn’t necessary. A2 tool steel is often chosen for moderate production runs and tooling with less demanding wear requirements.

summary

In the end, choosing between D2 and A2 tool steels all comes down to understanding your specific needs. Whether it’s the superior wear resistance of D2 or the toughness and versatility of A2, each steel has its strengths. By carefully considering the demands of your work and the tools you need, you can make an informed choice that ensures both efficiency and durability.