1.2379 tool steel(cold work tool steel)—heard of it? I work with steels often, and here’s my take: This steel has high carbon and chromium levels. It resists wear well and lasts long, which is why many choose it for cold work tools. But what makes it different from AISI D2 or SKD11(cold work tool steel)? I don’t think it’s just about hardness. There’s something else people might miss. I believe its versatility comes from hidden traits we rarely discuss. Let’s explore.

Definition and Composition

1.2379 tool steel(cold work tool steel) is like the unsung hero of cold work tools. It’s a high-carbon, high-chromium steel that hardens on its own when exposed to air, and honestly, I can’t recommend it enough if you’re looking for durability. It’s tough as nails, resisting wear and abrasion with ease. I think the magic really lies in its microstructure, packed with carbides that give it this unyielding strength. When heat-treated, it reaches a tough 60-62 HRC hardness—perfect for those heavy-duty jobs where you need something that won’t back down.

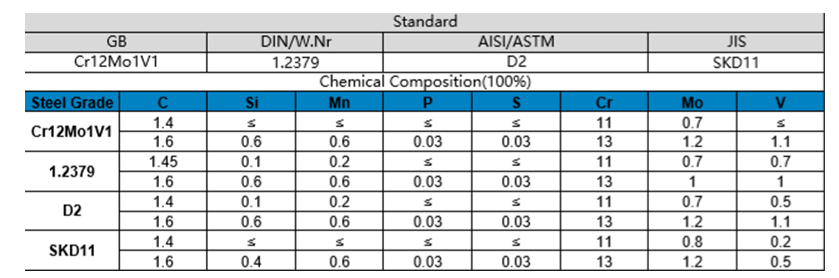

Chemical Composition

1.2379 tool steel includes carbon (C) at 1.45–1.60%, silicon (Si) at 0.10–0.60%, manganese (Mn) at 0.20–0.60%, chromium (Cr) at 11.0–13.0%, molybdenum (Mo) at 0.70–1.20%, vanadium (V) at 0.70–1.10%, phosphorus (P) at ≤0.030%, and sulfur (S) at ≤0.030%.

This mix gives the steel high wear resistance, strong compression handling, and stable dimensions. Based on my experience, the high chromium also helps it resist rust in air and freshwater.

Many compare 1.2379 tool steel to steels like AISI D2, SKD11, and Cr12Mo1V1(cold work tool steel). I suggest using it for cold work jobs where you need extreme wear resistance and high strength under pressure.

Properties and Characteristics

The key characteristics

1.2379 tool steel is known for its high wear resistance and excellent cutting strength, making it suitable for applications requiring durability and precision. After proper heat treatment, the steel can achieve a hardness of 62-63 HRC, which provides it with enhanced strength and resilience.

1.2379 tool steel exhibits key properties, including a density of 7.7 g/cm³, an elastic modulus of 190–210 GPa, a thermal expansion coefficient of 10.4 x 10⁻⁶/°C (20–100°C), a thermal conductivity of 20 W/(m·K) at 20°C, and a specific heat capacity of 460 J/(kg·K) at 20°C.

The key characteristics

1.2379 tool steel include a hardness of up to 63 HRC after quenching and tempering, ensuring excellent strength and durability. It exhibits remarkable thermal stability, maintaining structural integrity at temperatures up to 400°C, with a thermal conductivity of 23.0 W/m·K within this range. Additionally, its wear resistance is significantly enhanced through vacuum degassing and spheroidizing annealing processes during manufacturing, making it an ideal choice for high-performance tools.

The steel’s microstructure consists primarily of primary carbides (mainly M₇C₃ type) embedded in a martensitic matrix. These carbides are responsible for the steel’s exceptional wear resistance but may form clusters along the rolling direction, affecting its uniformity.

Additional Characteristics

1.2379 tool steel include a machinability rating of 2 out of 10 on a scale of 1-10, indicating it is difficult to machine. It has moderate corrosion resistance, classified as Class 1 on a scale of 0-5. The weldability of this tool steel is poor, making it less suitable for applications that require welding. However, it can be polished to a high finish, providing an aesthetically pleasing surface.

This tool steel’s excellent dimensional stability and high compressive strength make it a great choice for demanding applications, though its poor weldability should be considered when planning for fabrication.

Applications

1.2379 tool steel is widely utilized across various industries due to its exceptional properties, including high wear resistance, good cutting strength, and excellent pressure firmness. Its versatility makes it ideal for tools and components that require durability and precision in demanding environments.

Cold Working Tools

1.2379 tool steel is highly favored for cold working applications, where tools must withstand high stress and maintain dimensional accuracy. Common uses include: Precision stamping and blanking dies . Punching and cutting dies for stainless steel, brass, copper, and zinc sheets . Deep drawing and forming dies . Cold extrusion tools – Thread rolling dies and rolls.

Cutting Tools

The steel’s strength and resistance to wear make it suitable for cutting applications. Key cutting tools made from 1.2379 include: Industrial cutting knives and blades .Shear blades for strip and sheet metal (up to 10 mm thickness).Circular cutters for cold rolled strip . Paper cutting knives – Wire cutting tools.

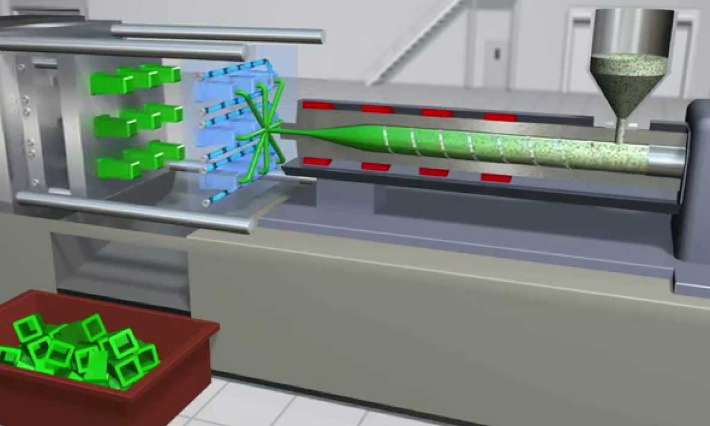

Plastic Processing

In plastic processing, 1.2379 tool steel excels in handling abrasive polymers and other challenging materials. Common applications include: Injection molds for abrasive polymers ,Thermoforming tools , Plastic mold liners.

Wear Parts

1.2379 tool steel is also ideal for wear-resistant components that endure harsh conditions. These include: Measuring tools and gauges. Bearings and rollers – Machine components subject to high wear.

Other Applications

Beyond its use in tools and components, 1.2379 tool steel is also utilized in various other specialized applications: Coining molds ,Rolling mills ,Lamination dies for electrical steel sheets ,Tire shredders and scrap choppers ,High-speed blanking molds for silicon steel sheets.

1.2379 tool steel is particularly suited for long production runs, offering high dimensional stability and resistance to abrasive wear. It is often selected for applications where D3 type steels (2% carbon) might be too brittle or prone to cracking.

International Grades Equivalent to 1.2379 Tool Steel

1.2379 tool steel, recognized for its durability and high wear resistance, is standardized under DIN (German Institute for Standardization) but has equivalents across various global standards. These equivalents share similar properties but may differ in composition and intended applications.

AISI D2 Tool Steel (United States)

AISI D2 tool steel(cold work tool steel), originating from the United States.It is a tool steel whose composition is similar to 1.2379, with slight variations in trace elements like sulfur (S) and phosphorus (P). It is primarily utilized in applications such as cold-work dies, shear blades, and thread-rolling dies. Notably, AISI D2 is generally interchangeable with 1.2379, although it may necessitate different heat treatment protocols to achieve optimal performance.

JIS SKD11 Tool Steel (Japan)

JIS SKD11 tool steel(cold work tool steel) is a Japanese steel grade.It shares a similar composition to 1.2379 in terms of chromium and carbon content, but with stricter controls on impurities. This steel is commonly used in precision molds and high-stress cutting tools, and it is particularly distinguished by its superior toughness, especially within Japanese industrial practices.

GB Cr12Mo1V1 Tool Steel (China)

GB Cr12Mo1V1 tool steel(cold work tool steel), a Chinese steel grade, closely aligns with 1.2379. However, its standards permit broader tolerances for molybdenum and vanadium. This composition makes it particularly suitable for applications requiring high-precision stamping dies and cold extrusion tools..

DIN X155CrVMo12-1 Tool Steel (Germany)

DIN X155CrVMo12-1 tool steel(cold work tool steel), originating from Germany, features a composition that closely resembles 1.2379, with the primary variations lying in nomenclature stemming from regional standardization practices.

K110 Tool Steel (Böhler-Uddeholm, Austria)

K110 tool steel(cold work tool steel), produced by Böhler-Uddeholm in Austria.It has a composition that closely matches 1.2379. It focuses on high purity to improve polishability. This steel is commonly used in plastic injection molds.

Key Differences Between International Grades Equivalent

When comparing 1.2379 tool steel with its equivalents, it is essential to consider several factors, including heat treatment requirements, regional standards, and application-specific performance. These subtle differences play a significant role in selecting the most suitable material for specific industrial applications.

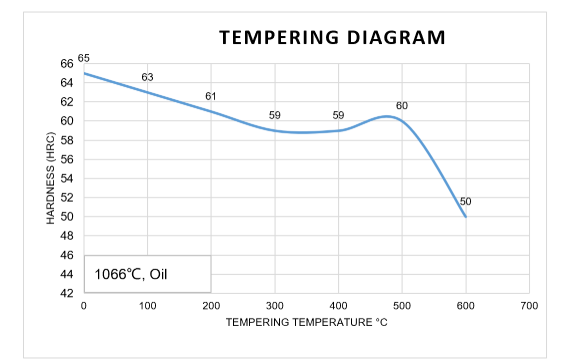

Heat Treatment Requirements

1.2379 tool steel often undergoes cryogenic treatment after quenching, with temperatures between -70°C and -80°C. This process can increase hardness by up to 3 HRC. On the other hand, SKD11 tool steel typically undergoes multiple tempering cycles, aiming to balance hardness and toughness for more versatile applications.

Regional Standards

Different regions have their own standards for tool steels, which can lead to slight variations in their properties: AISI D2 allows slightly higher sulfur content, which can affect machinability but requires stricter control during forging to ensure quality. Chinese Cr12Mo1V1 tool steel may show slight differences in molybdenum ranges, which can influence its wear resistance in certain applications.

Application-Specific Performance

1.2379 and its equivalents excel in specific areas of tooling: K110 tool steel is favored in the European markets for applications such as molds requiring high surface finish. SKD11 dominates in Asian precision tooling industries, where high toughness and wear resistance are crucial.

These differences help in selecting the right steel grade based on specific regional standards and performance requirements.

Advantages and Processing Considerations

1.2379 tool steel offers several key advantages that make it highly suitable for demanding applications, particularly in cold work tooling and wear-resistant components.

Advantages:

1.2379 tool steel offers several notable advantages that make it highly suitable for demanding applications. Its superior wear resistance, due to high carbon and chromium content, ensures long-lasting cutting edges and excellent performance in abrasive environments. After heat treatment, it can achieve remarkable hardness of up to 62 HRC, providing exceptional strength and durability. Additionally, it maintains good dimensional stability with minimal warping during heat treatment, which is crucial for precision tool production. While it has moderate corrosion resistance when polished, allowing for some protection against rust and oxidation, 1.2379 also boasts high compressive strength, enabling it to withstand heavy loads and impacts without significant deformation, making it ideal for high-stress environments. The steel’s good machinability in its annealed condition facilitates efficient manufacturing of tools, and its nitriding capability, enhanced by special heat treatments, improves surface hardness and wear resistance further. Furthermore, 1.2379 possesses secondary hardening properties that allow for additional surface treatments, such as coatings, enhancing overall performance. It strikes a balanced blend of toughness and hardness, delivering reliable strength and impact resistance across various heavy-duty applications, while also maintaining excellent edge retention for extended periods, essential for cutting tools in precision operations.

Processing Tips:

For processing 1.2379 tool steel, annealing involves heating it to 800–850°C under protective gas.And then slowly cooling it to ≤250 HBW to relieve stresses and soften the material. Quenching requires austenitizing at 975–1040°C, followed by oil or air cooling. To retain optimal hardness, low-temperature tempering at 150–200°C is recommended, achieving hardness ≥61 HRC.

These processing guidelines, combined with 1.2379 tool steel’s superior properties, make it a reliable choice for cold work tooling, precision cutting instruments, and wear-resistant components in high-performance industrial environments.

summary

In the world of tool steels, 1.2379 tool steel stands out as a powerful and versatile choice, offering unmatched wear resistance and strength. Whether you’re working with cutting tools, molds, or precision dies, this steel delivers exceptional performance in demanding applications. As technology advances, the value of materials like 1.2379 tool steel continues to shine, reminding us that the right material can make all the difference in achieving success. Keep exploring, and you’ll find that the best tools are built from the strongest steels.