For global service

High-speed Tool Steel

workers

Company area/acres

Workshop area/SQM

Product Quantity

FCS High-speed Tool Steel OEM Factory

High-speed Tool Steel

Our High-Speed Tool Steel Offerings:

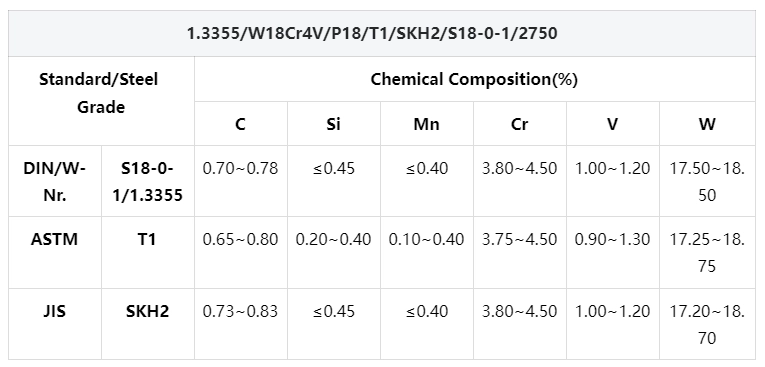

- 1.3355/W18Cr4V/P18/T1/SKH2/S18-0-1/2750: This exceptional high-speed steel boasts superior hardness, toughness, and durability. It excels in wear resistance and demonstrates excellent ductility, thermal stability, and red hardness, making it an ideal choice for applications requiring robust performance and efficiency.

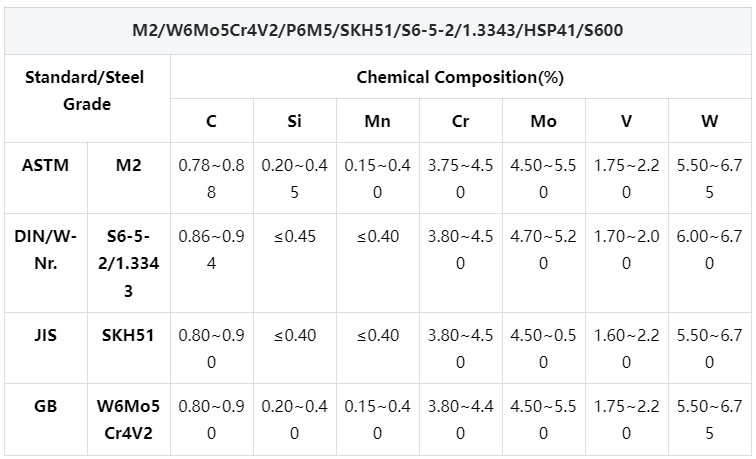

- M2/W6Mo5Cr4V2/P6M5/SKH51/S6-5-2/1.3343/HSP41/S600: Known for its remarkable hardness and wear resistance, M2 high-speed steel is perfect for manufacturing tools designed to cut through the most challenging materials. It combines high toughness with excellent heat softening resistance, ensuring longevity and reliability during operation.

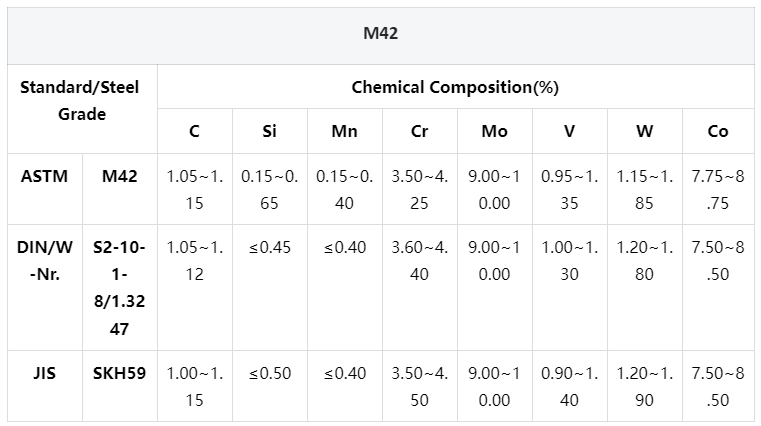

- M42: M42 high-speed tool steel is celebrated for its outstanding wear resistance and fatigue resistance. It offers significant hardness and thermal hardness, making it a preferred choice for high-performance cutting tools and applications under extreme conditions.

- Custom High-Speed Tool Steel Solutions: At Fu Cheng Tool Steel, we understand that each project presents unique challenges. That’s why we offer customizable high-speed tool steel grades tailored to your specific requirements, ensuring you receive the perfect tool for your needs.

Outstanding properties of high speed tool steel

High hardness and wear resistance

Even in the high temperature and high pressure cutting environment, high speed tool steel can still maintain excellent hardness, cutting edge lasting sharpness, greatly extend the service life of the tool, reduce the frequency of replacement, and effectively reduce production costs.

Outstanding thermal hardness

In the face of high temperatures generated by high-speed cutting, the thermal hardness of high-speed tool steel to ensure that its cutting performance is not affected, and always maintain high precision machining and excellent surface quality to meet the demanding needs of high-end manufacturing.

Good toughness

When subjected to shock and vibration, high-speed tool steel with good toughness, to protect the stability of the machining process, to avoid tool breakage, suitable for complex and variable machining conditions.

Advanced Production Equipment & Processes:

The tool steel factory has a complete set of equipment and complete process flow required for the production of hot work tool steel.

Extended Service Life:

Superior Performance & Corrosion Resistance:

Unmatched Cutting Performance:

The premium high-speed tool steel designed for exceptional cutting performance. Achieve working efficiency with speeds faster than traditional high-carbon steels, ensuring superior results in your manufacturing processes.

SIZE RANGE

- Round Bar:

- Flat bar:

SURFACE CONDITION

- Black;

- Peeled/Grinded;

- Turned/Machined/Bright/Milled

- Customized services available upon request

1.3355

TOOL STEEL GRADES

APPLICATION

Metal Cutting Tools

- Precision machining of carbon/alloy steels, cast irons, and non-ferrous metals

- Production of twist drills, end mills, lathe tools, and gear hobs for automotive transmission systems

- Heavy-duty planer blades and shaper tools for industrial machining centers

Forming & Stamping

- Cold-work dies for fastener manufacturing (bolts, screws, rivets)

- Punches and shear blades for sheet metal processing

- Thread rolling dies for high-volume screw production

High-Efficiency Machining

- CNC automatic lathe tools for mass production environments

- Reamers and broaches for aerospace hydraulic components

- Circular saw blades for metal cutting bandsaws

Specialized Tooling

- Woodworking carbide-tipped saw bodies requiring high rigidity

- Extrusion dies for aluminum profile manufacturing

- Injection mold cores for glass-filled engineering plastics

M2

TOOL STEEL GRADES

APPLICATION

- Drill bits and end mills for hardened steels (HRC 45-55) in automotive gear machining

- High-feed milling cutters for titanium aircraft components

- Threading tools for oil/gas pipeline connectors

High-Temperature Tooling

- Hot forging dies for aluminum wheel rims

- Extrusion mandrels for copper alloy profiles

- Injection molding cores for high-glass-fiber reinforced polymers

Wear-Resistant Components

- Cold heading dies for ISO metric fastener production

- Slitter blades for silicon steel sheet processing

- Rotary cutting knives for food/pharmaceutical packaging films

Advanced Manufacturing

- CNC engraving tools for carbon fiber composite machining

- Reamers for medical implant (hip/knee prosthesis) finishing

- Gear shaving cutters in wind turbine transmission systems

M42

TOOL STEEL GRADES

APPLICATION

Precision Cutting and Machining Tools

- High-performance drill bits and end mills for machining hardened steels (e.g., automotive transmission gears) and superalloys

- Thread rolling dies and taps for producing high-strength fasteners in aerospace and automotive industries

- Gear hobs and broaches for precision machining of turbine components

Advanced Cold Work Tooling

- Cold heading dies for manufacturing ISO-grade bolts, screws, and rivets with extended service life

- Precision blanking punches and shear blades for sheet metal processing in electronics enclosures

- Progressive dies for stamping high-hardness spring steels

Wear-Resistant Components

- TiN-coated punches for M16 hexagon trimming molds, significantly improving durability

- Slitter knives for processing abrasive materials like silicon steel and carbon composites

- Extrusion tooling for copper alloy profiles requiring high thermal stability

Specialized Industrial Applications

- Injection mold cores for glass-fiber-reinforced engineering plastics (e.g., PEEK, PPS)

- Rotary cutting tools for pharmaceutical blister packaging machines

- Reamers for finishing medical implants requiring micron-level precision

Why Choos FCS High-speed Tool Steel

Cost-effective customized services

FCS tool steel can meet the customer’s custom tool steel needs, according to the technical agreement provided by the customer. At the same time, we have our own tool steel factory, which can provide customers with cost-effective tool steel customization costs. Help customers reduce unnecessary costs.

Large spot stocks

With a monthly production capacity of 2,000 tons, we also have a large stock of high speed tool steel, available in a variety of standards and grades to meet the needs of customers from different countries. At the same time, these inventory items include steel round rods and steel flat rods.

Customizable sizes

The size range of our tool steels in different shapes also varies. For example, the length range of the plate bar is 3000-5800mm, the width range is 200-800mm, and the thickness is 16-300mm. The length of the round bar is the same as the plate bar, and the diameter is 16-400mm. In addition, we can also provide customers with dimensional customization of high-speed tool steel.

Free samples available

FCS tool steel attaches importance to customer purchase experience, supports customers to apply for free sample testing, reduces the risk of purchasing decisions, and enhances the confidence of product experience.

Green and low-carbon production

Electric furnace steelmaking combined with waste heat recovery technology, carbon emissions are 35% lower than the traditional process, in line with international environmental standards