For global service

Plastic Tool Steel

workers

Company area/acres

Workshop area/SQM

Product Quantity

FCS Plastic Tool Steel OEM Factory

Plastic Tool Steel

Our key plastic tool steel products include:

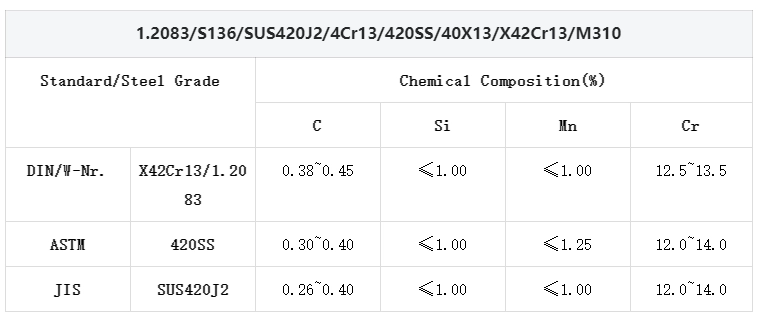

- 1.2083/S136/SUS420J2/4Cr13/420SS/40X13/X42Cr13/M310

1.2083 plastic tool steel variant is renowned for its exceptional wear resistance and high fatigue strength. It boasts excellent heat treatment, polishing, and welding performance, making it perfect for applications where durability is critical. This eco-friendly option also offers outstanding corrosion resistance and great machinability, backed by significant demand in the market. - H11/1.2343/4Cr5MoSiV/4X5MΦC/W300/SKD6/X38CrMoV5-1

Our H11 series exemplifies resilience with superb corrosion resistance and high hardness levels. Known for its excellent thermal stability and cutting performance, this grade provides outstanding wear resistance while maintaining high purity, ensuring efficacy under varied operating conditions. - 440C/9Cr18Mo

The 440C plastic tool steel is a high-performance alloy that combines excellent corrosion resistance, wear resistance, and hardness. Its remarkable strength and heat resistance make it ideal for high-temperature and high-load applications, delivering reliability in even the most demanding environments. - Custom Solutions

At Fu Cheng Tool Steel, we understand that each operation is unique. That’s why we offer customization services for our plastic tool steel products, allowing you to specify the type, composition, and dimensions that best suit your requirements.

Core properties of plastic tool steel

High strength and resistance to deformation

Specially designed for plastic mold high-alloy formula (such as adding Cr, Ni, Mo), to ensure that the material in the high-pressure injection environment to resist plastic deformation, avoid mold surface sag, corner collapse and other problems, extend the service life.

Excellent processing adaptability

Pre-hardening treatment (such as HRC 30-40) ensures that the material maintains high accuracy in cutting and EDM, supports rapid prototyping of complex cavity molds, and shortens the production cycle.

High mirror polishing properties

The special smelting process (vacuum degassing + electroslag remelting) ensures the purity of the material, and can reach Ra≤0.05μm after polishing, which meets the optical surface requirements of high-end plastic products such as automobile lamp shades and transparent packaging.

Advanced Production Equipment & Processes:

Extensive Inventory of High-Quality Plastic Tool Steels:

We keep a mass stock for various plastic tool steel type, including steel round bar, steel flat bar, and etc.

Quality assurance:

High-Quality Plastic Tool Steel in Various Shapes:

Round bar, plate bar can be provided, and customized shape services can be provided if there are special requirements.

SIZE RANGE

- Round Bar:

- Flat bar:

SURFACE CONDITION

- Black;

- Peeled/Grinded;

- Turned/Machined/Bright/Milled

- Customized services available upon request

1.2083

TOOL STEEL GRADES

APPLICATION

1.2083 steel is mainly used in the production of PVC molds, wear-resistant and filling molds, including thermoset plastic molds and long-life molds.420SS tool steel is suitable for manufacturing hot oil pumps, valve plates, valve bearings, medical instruments, springs, tools, nozzles, seats and other parts with high hardness and high wear resistance.S136 die steel is often used in corrosion-resistant plastic material molds, electronic parts, discarded knives, tableware and so on.

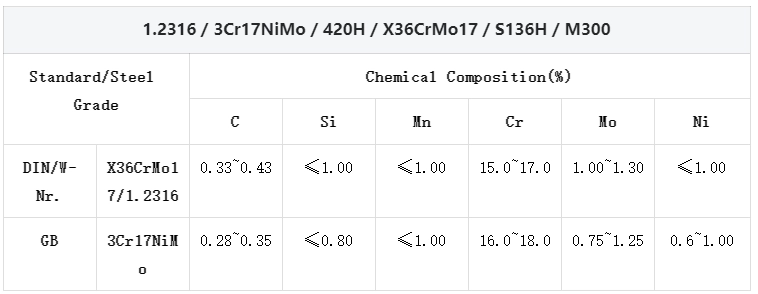

1.2316

TOOL STEEL GRADES

APPLICATION

1.2316 Tool Steel

- Primary Application: Corrosive thermoplastic processing

- Specialization:

• Injection molds for PVC, POM, and acid-resistant polymers

• High-gloss/mirror-finish components

• Optical-grade transparent products - Surface Quality: Achieves SPI A1/A2 polish standards

Cr17NiMo-MOD Steel (Modified 420 Martensitic Grade)

- Key Attributes:

• Enhanced corrosion resistance

• 32-38 HRC hardness with exceptional machinability - Target Applications:

• Medical device molds requiring chemical sterilization

• Transparent polymer optics production

• Precision mirror-surface tooling

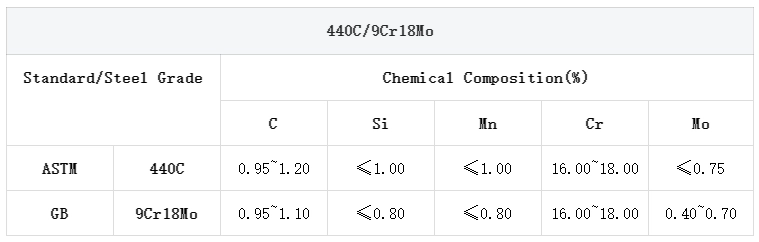

440C

TOOL STEEL GRADES

APPLICATION

9Cr18Mo steel is suitable for bearing, turbine blade, nozzle, valve, plate ruler, cutter and scissors with good corrosion resistance.

Why Choos FCS Plastic Tool Steel

Stable dimensional accuracy

Strict quality control system ensures the dimensional accuracy and stable performance of each batch of steel, providing you with reliable product guarantee.

Cutting-edge metallurgical technology

Adopting electric arc furnace refining (EAF) + furnace refining (LF) duplex process, the impurity content is controlled up to international standards (e.g. P≤0.015%, S≤0.003%), to guarantee the homogeneity of materials.

Optional surface state

Our plastic tool steels offer a wide choice of surface states. For example: black; Peeling/grinding; Turning/machining/polishing/grinding, etc. If you have other special requirements, our technical team will also help you.

Hot work tool steel technology empowerment

FCS tool steel relies on the experience of hot work steel field (such as H13 mold steel production), innovative application of multi-directional forging technology, to improve the high temperature stability and thermal fatigue resistance of plastic tool steel, adapt to the processing of high-temperature plastics such as PC, PA, etc.

Complete variety of plastic tool steels

FCS tool steel can provide a variety of grades and specifications of hot work tool steel, such as: 1.2083, SUS420J2, 420SS, 1.2316, 420H, 440C and other tool steel. In order to meet the needs of different customers, we provide one-stop purchasing service for you.