For global service

Cold work tool steel

workers

Company area/acres

Workshop area/SQM

Product Quantity

FCS CoLD WORD Tool Steel OEM Factory

COLD WORK TOOL STEEl

High-Quality Cold Working Tool Steel Solutions

Our extensive range of cold working tool steel products includes some of the most sought-after grades:

- D3 (SKD1/1.2080/X210Cr12/X12/K100/Cr12): Renowned for its wear resistance and ability to hold a sharp edge, making it ideal for applications requiring precision and durability.

- D6 (1.2436/X210CrW12/Cr12W): Known for its excellent toughness and high wear resistance, suitable for applications where longevity is crucial.

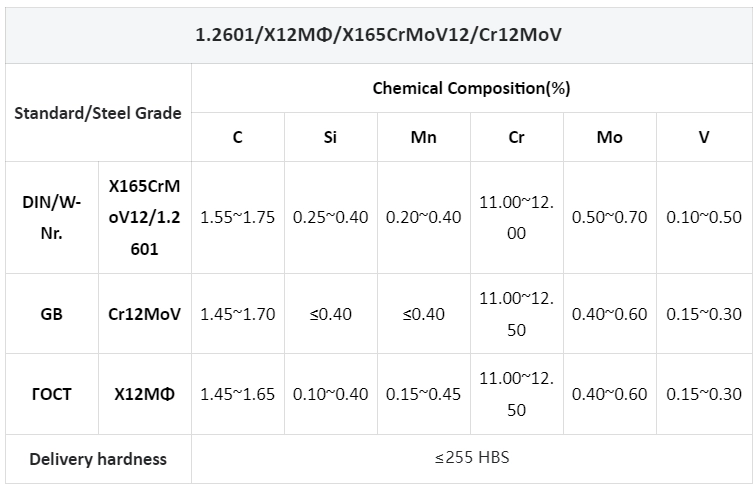

- 1.2601 (X12MΦ/X165CrMoV12/Cr12MoV): A versatile steel that offers high hardness and exceptional wear resistance.

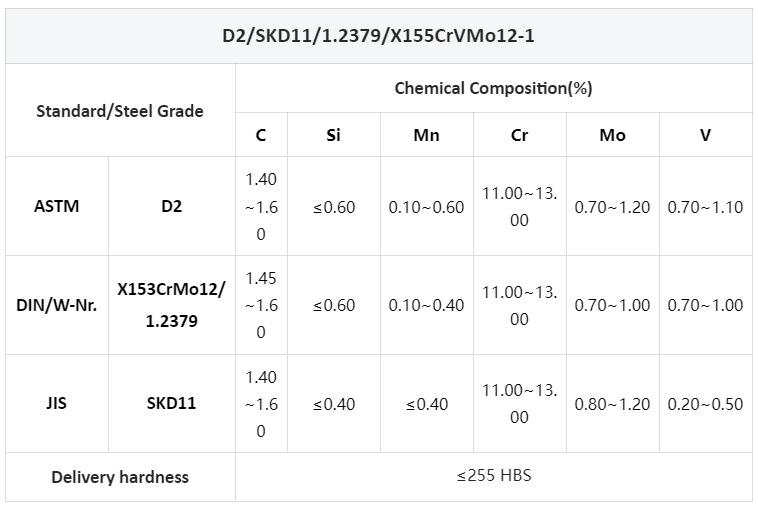

- D2 (SKD11/1.2379/X155CrVMo12-1): A high-carbon tool steel known for its outstanding abrasion resistance and toughness, often used in cold work tooling applications.

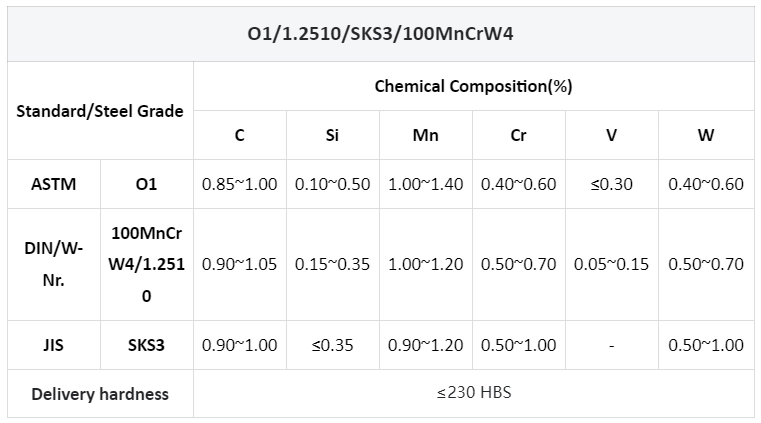

- 9CrWMn (O1/1.2510/DF-3/K460/SKS3/100MnCrW4/9XBГ): A high-performance tool steel that provides excellent hardness and wear resistance in demanding environments.

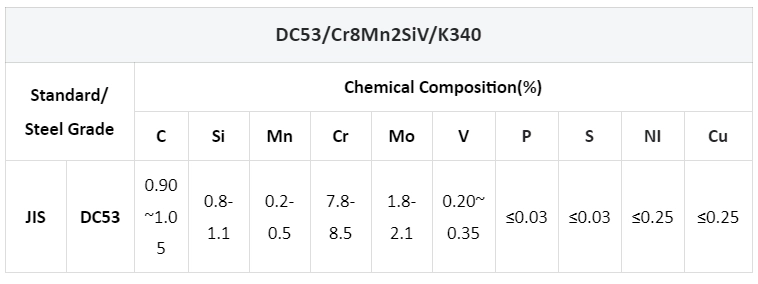

- DC53 (Cr8Mn2SiV/K340): A premium cold work tool steel offering outstanding wear resistance and form stability, ideal for high-precision tooling.

Core properties of FCS cold work tool steel

Ultra-high hardness and wear resistance

Cold work tool steel has excellent hardness (up to 60-64 HRC after heat treatment) and wear resistance through the scientific ratio of high carbon, high chromium (e.g. Cr content of 11%-13%) and alloying elements such as molybdenum and vanadium, which is suitable for high-load stamping, cutting and mold making and significantly extends the life of the tool.

Excellent corrosion and high temperature resistance

Chromium forms a dense oxide layer to resist corrosive media; molybdenum enhances high-temperature stability to ensure stable performance under complex working conditions.

Precision machining and heat treatment adaptability

The material has excellent processing performance after annealing, supporting the molding of complex molds; quenching + tempering process to flexibly adjust the balance of toughness and hardness to meet customized needs.

Wide range of applications

Covering automotive molds, precision tools, stamping dies, aerospace components, etc., suitable for high-speed cutting, cold extrusion and other high-precision scenarios.

Extensive manufacturing experience:

Tool Steel Factory Visit & Services:

Premium Tool Steel from Direct Manufacturer

Stable supply capacity:

SIZE RANGE

- Round Bar:

- Flat bar:

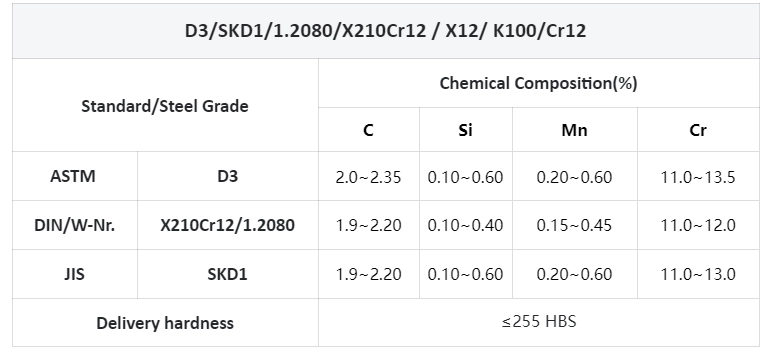

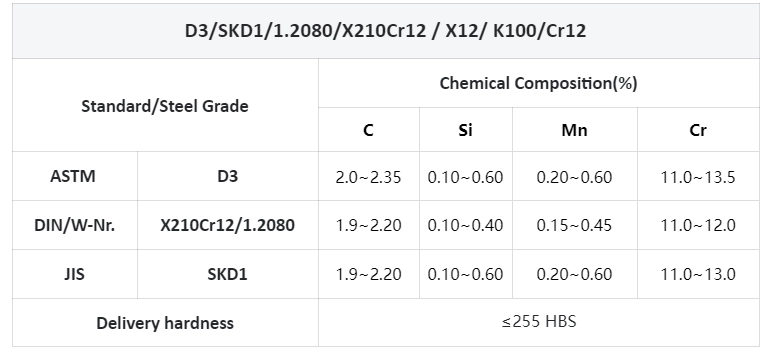

1.2080

TOOL STEEL GRADES

1.2080 & Its Equivalents

1.2080 (DIN/Germany), is a high carbon, high chromium cold work tool steel. It is also known as SKD1, D3, Cr12, X210Cr12, K100, or X12, and is known for its excellent wear resistance. Key properties include dimensional stability, medium toughness and resistance to abrasive wear. Its composition (1.9-2.2% C, 11-13% Cr) forms hard chromium carbide. It can be heat-treated to a hardness of 58-64 HRC, and if you want to increase its wear resistance, it can be ground and polished. Many people tend to confuse AISI D3 with D2 tool steel. Because the application of D3 is similar to D2 tool steel. But alloy tool steel D3 has better wear resistance of both steels.

APPLICATION

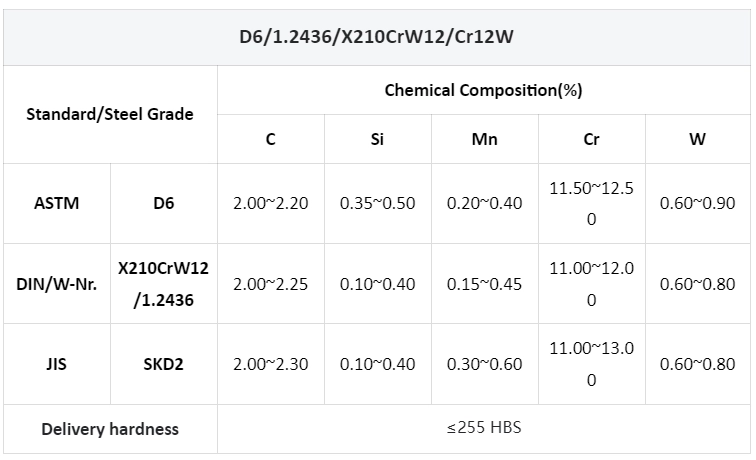

D6

TOOL STEEL GRADES

SKD2 & Its Equivalents

1.2436 Tool Steel (DIN/Germany), also designated as X210CrW12 or X12, is a high-carbon, high-chromium cold work steel containing 1.9–2.2% carbon and 11–13% chromium.

APPLICATION

1.2601

TOOL STEEL GRADES

APPLICATION

1.2379

APPLICATION

1.2510

APPLICATION

DC53

TOOL STEEL GRADES

APPLICATION

Why Choos FCS Cold WOrk Tool Steel

Fast delivery

Global

We proudly serve a diverse clientele across the globe, including customers in Southeast Asia, Europe, the Americas, the Middle East, and more. Our extensive partnerships reflect our commitment to delivering high-quality die steel and tool steel tailored to meet the unique needs of each market.

CUTTING-EDGE TECHNOLOGY

FCS tool steel adopts electric arc furnace refining + vacuum degassing technology to ensure material purity and composition uniformity, impurity control up to international standards (such as DIN 1.2379, JIS SKD11).

High packaging safety

We prioritize the safety and integrity of our products during transportation and storage to ensure maximum protection of our die and tool steels. Strong bundling: Our materials are professionally bundled to withstand the rigor of transportation and handling. This approach not only prevents damage, but also makes storage and inventory management much easier.Customizable PVC packaging: Choose from a variety of vibrant PVC color options tailored to your specifications. Whether you need color coding for easy identification or need specific branding requirements, our flexible packaging solutions have you covered.

Multinational standard cold work tool steels

Our cold work tool steels are engineered to deliver superior performance and durability for diverse applications, from manufacturing to tool production. Whether your project requires specific grades or custom solutions, our dedicated team is here to assist you in selecting the perfect steel for your needs.