Experienced Tool Steel Factory

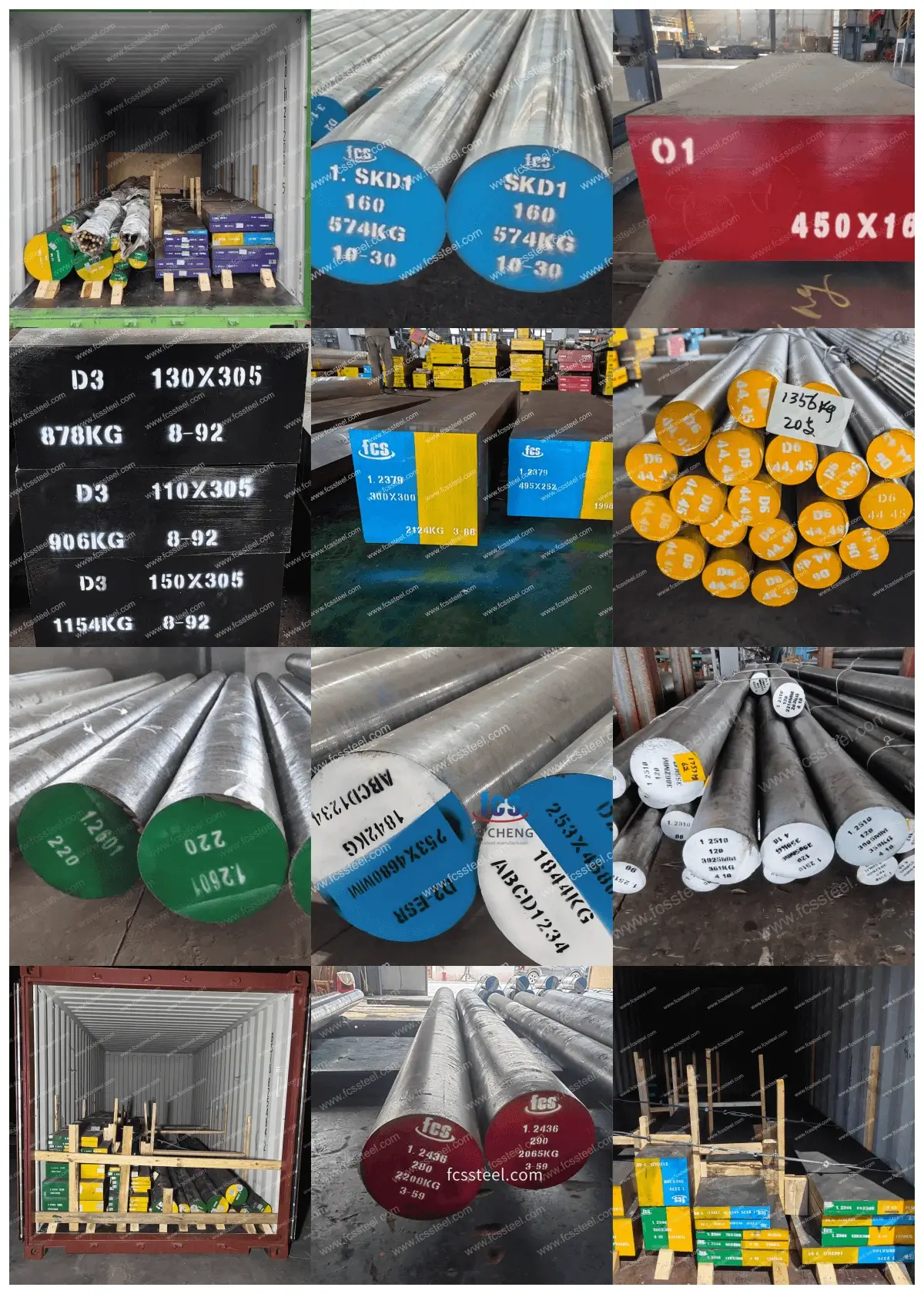

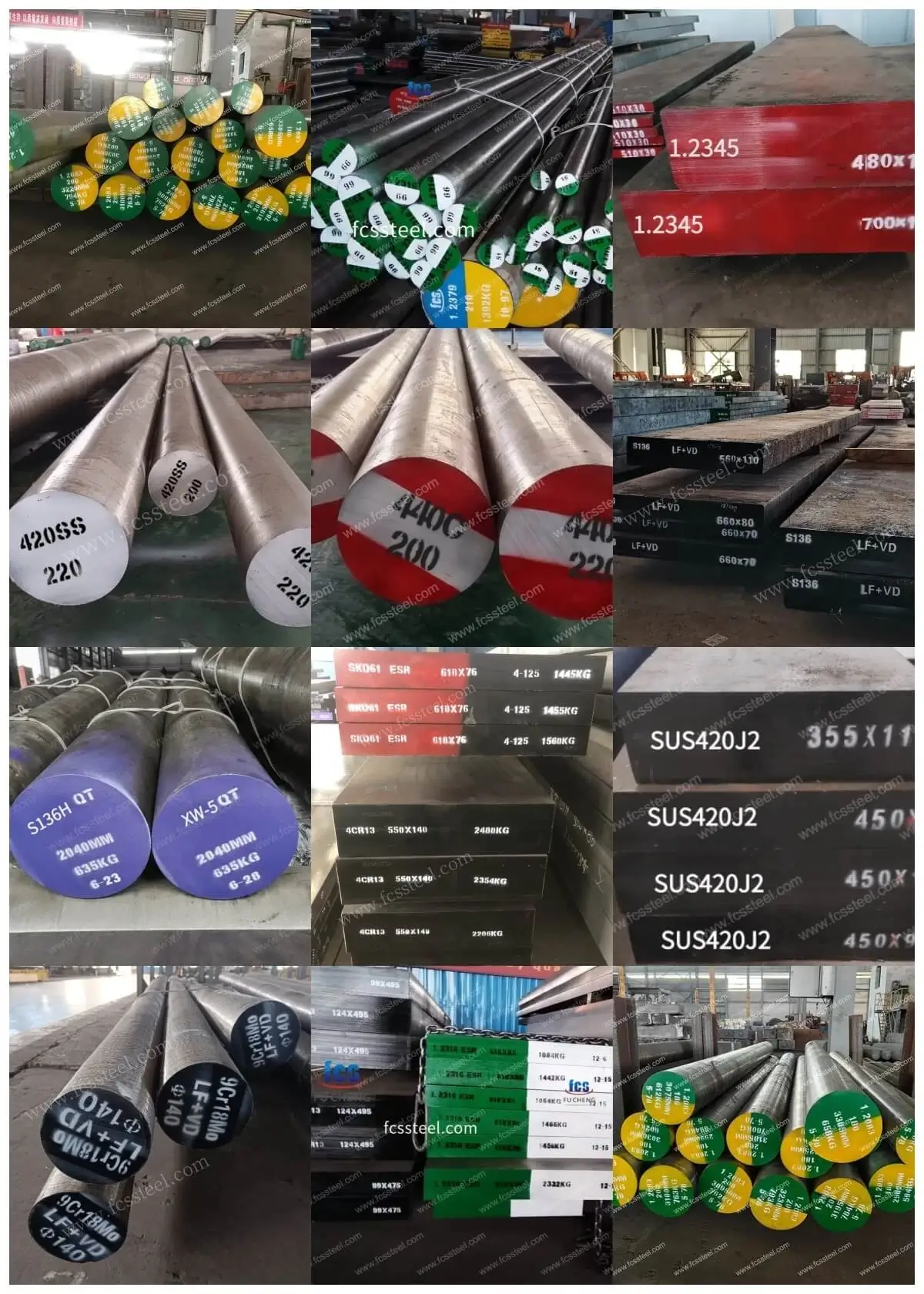

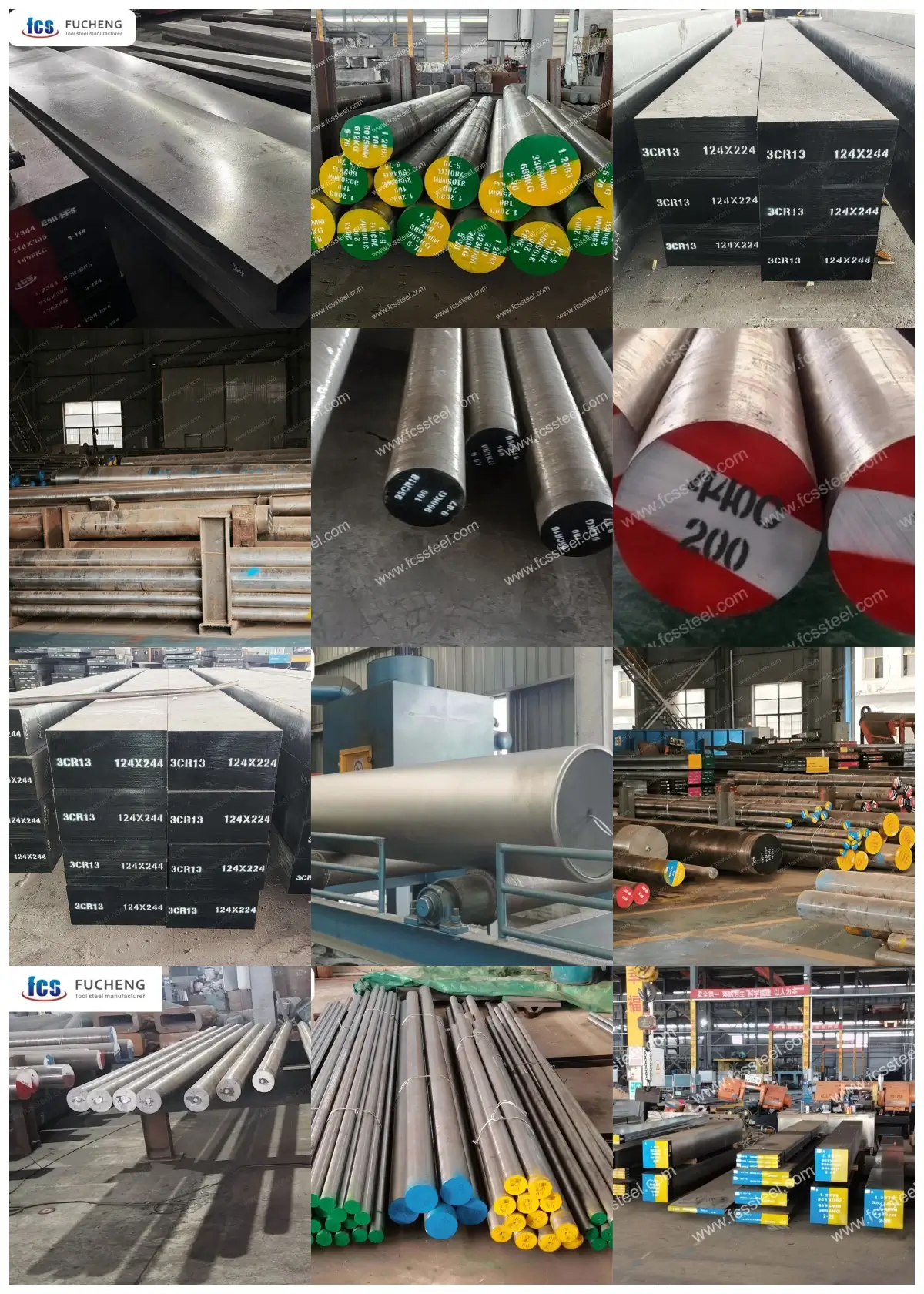

5000 tons/Day 1.2379|1.2344|1.21316|D2|H13|D6|SKD11|SKD61 in Stock for fast delivery

Factory direct with High-Quality Tool Steels: cold work tool steel, Hot Work,Plastic tool Steel,High-speed tool steel and Stainless Steel.

Cost savings 20-30% of compared to traditional

Tool Steel & Alloy Steel Supplier

Professional & Reliable

Support Global Tool Steel Standard China (GB) For All Steel Types

Tool Steel Certification

ISO 9001 & SGS

ISO 9001

FCS Tool Steel has a global standard production capacity covering mainstream systems such as GB/DIN/ASTM/JIS, and direct factory supply from the source ensures that the material meets the standard accurately. Through the strict quality control of ISO9001 quality system certification, we provide our customers with reliable tool steel solutions with excellent performance and longevity with traceable manufacturing processes and consistency throughout the chain, significantly reducing application risks.

SGS

FCS tool steel is certified by SGS to ensure that each batch of material meets international safety and performance standards, providing your global supply chain with inspection-free quality assurance and significantly reducing trade compliance risks and inbound testing costs.

Professional Tool Steel Factory

FCS Tool Steel, with 18 years of deep expertise in the tool steel industry, leverages full-process control capabilities to eliminate obstacles for you. Established in 2007 and specializing in tool steel production, FCS boasts an annual capacity of 25,000 metric tons and maintains long-term strategic inventory reserves of 5,000 metric tons.

Equipped with a complete production line—spanning steelmaking, forging, annealing, turning, milling, and rigorous quality inspection—we ensure excellence at every stage. Backed by ISO 9001 certification, our core commitment to batch-to-batch consistency significantly reduces tool failure risks. Our precision-engineered tool steels, crafted through profound experience, deliver exceptional wear resistance, superior dimensional stability, and outstanding machinability. They empower you to manufacture longer-lasting, higher-precision molds and cutting tools, enhancing production efficiency and product competitiveness.

years of expertise

Area/Square Meter

Annual output/Tons

Long-term stock levels/Tons

OEM/ODM

DESIGN

PACKAGING

Source Factory:

Triple assurance of capacity, cost & delivery

Relying on the advantages of powerful source factories, FCS provides you with a full range of guarantees and significantly improves the value of procurement:

– Cost Reduction.

– Efficiency Enhancement .

– Hassle-Free Delivery of Source Procurement Solutions.

Significantly reduce overall costs and ensure sufficient capacity:

Fully utilizing the advantages of source factories not only ensures sufficient capacity, but also effectively reduces your total procurement costs.

Efficient delivery, on-time and reliable, relieving supply chain worries:

Integrating efficient production chain and strong inventory system to ensure on-time delivery, completely eliminating your supply chain worries.

Flexible Response to Customized Needs, Professional Solutions for Worry-Free Production:

Whether you need a standard stock product or a customized specification for an emergency production run, the FCS team can provide reliable solutions with competitive pricing and in-depth technical expertise. Specialized logistics systems and a strict commitment to performance ensure that your production schedules stay on track.

Advantage tool steel Cutting machine

Get Top 1 Stool Steel Supplier

Sawing Machine

FCS Tool Steel Processing Plant leverages an advanced cluster of 10 sawing machines, demonstrating significant scale and flexible manufacturing capabilities in precision tool steel cutting. This center delivers high-precision processing of round bars and plates with strict tolerance control, minimizing material waste. The scaled configuration significantly boosts daily cutting capacity and achieves full specification coverage for round bars and plates across all thicknesses. Supported by efficient machine coordination, it ensures qualified cutting surface roughness, enables 24-hour rapid response, and compresses order delivery cycles to 60% of the industry average.

Core Advantages:

- Scalable Precision Processing: 10 high-precision saws for round bars and plates.

- Superior Accuracy & Waste Reduction: Minimizes material loss through strict tolerance control.

- Full Specification Coverage & High Capacity: Processes all thicknesses of round bars and plates, exceeding conventional daily tonnage.

- Rapid Flexible Manufacturing:24-hour rapid response capability.Handles both high-volume standard parts and low-volume custom orders.

- Efficient Quality & Delivery: Ensures qualified surface roughness and reduces delivery time to 60% of industry average.

Turning Machined

Turning machines are primarily used for processing round tool steel bars. They remove the scale (oxidized layer) from hot-rolled or forged round bars, refining the surface to precise dimensional tolerances (e.g., 0-+2mm). Equipped with rotating chucks and cutting tools, these machines enable cylindrical machining, ensuring uniform diameter and surface finish critical for components like punches, ejector pins, and shafts. Their precision minimizes material waste and prepares the stock for subsequent heat treatment or finishing.

Peeling Machine

FCS Tool Steel Mill utilizes a state-of-the-art stripping machine for efficient surface treatment of round bars (φ10mm-φ700mm). This process provides smooth-surfaced, dimensionally accurate pre-treated material that greatly reduces the cycle time for subsequent heat treatment or machining. Particularly for high-alloyed tool billets (e.g. 1.2379, DC53), stripping eliminates surface stress concentration points and improves the fatigue life and machining stability of the final tool – demonstrating the mill’s leading-edge technology and large-scale machining capabilities in raw material pretreatment.

Key Benefits

- Accurate Defect Removal: Multiple rollers provide precise removal of surface defects.

- Tight quality control: Surface roughness and dimensional tolerances are maintained within specified limits.

- Minimized Waste: Adaptive feed system limits material loss to <1.5%.

- Downstream Efficiency: Provides smooth, dimensionally accurate blanks and shortens post-processing cycles.

- Enhanced Tool Performance: Eliminates stress points (critical for high alloy steels such as 1.2379/DC53) to improve fatigue life and machining stability.

Milling Machines

Milling machines specialize in processing tool steel plates, shaping flat surfaces and edges to strict specifications. Using rotary cutters, they remove excess material from as-rolled or forged plates, achieving flatness and dimensional accuracy (e.g., thickness tolerances of 0-+2mm). These machines are essential for preparing die bases, mold inserts, and structural components, ensuring consistent flatness and surface roughness that meet the high standards of die casting, stamping, and injection molding applications.

Amazing

some description

FCS STEEL ADVANTAGE

Factory Price

Leading tool steel manufacturer.Direct factory pricing for quality cold and hot work tool steels while maintaining industry-leading quality. Our vertical integration enables cost-effective production of high-hardness tool steel rods, cutting tool steels and custom alloys for precision and durability.Cost savings of 20-30% compared to traditional distributors, supported by iso certification process.

Free Sample

Eliminate guesswork with free samples tailored to your needs. We can provide free samples of various grades of tool steel and stainless steel. For example: 1.2379, D2, 1.2344, SKD61, H13, SKD11 tool steel, AISI 440C, etc. By testing free samples, you can not only confirm machining performance before placing a bulk order. You can also compare wear patterns at the stainless steel/tool steel interface.

Volume Production Capabilities

The large-scale production infrastructure at our FCS plant allows us to handle the largest tool steel orders while maintaining strict quality control in every ton of product produced.FCS TOOL STEEL has separate production lines with a capacity of 2,000 tons per month, and we systematically schedule production to optimize efficiency and quality consistency.

Full life-cycle services

FCS Tool Steel provides comprehensive services. Pre-sale 8-hour technical consultation response, experienced business team to receive inquiries within 8 hours to provide detailed free advice on material selection, processing requirements, including grade comparison, performance prediction, cost analysis. After the specifications are determined, we will strictly control the production process and carry out a number of quality inspections; after delivery, we provide comprehensive technical support, including unlimited counseling, performance problem investigation, and so on.

Packaging and protection

Packaging customization and protection are at the heart of our commitment to customer satisfaction.FCS Plant offers highly customized packaging solutions.The dedicated team at FCS Plant meticulously evaluates the vulnerability of each product. For tool steel that is prone to rust, we utilize state-of-the-art rust-resistant materials that create a strong barrier against corrosion. When it comes to large steel pieces, we use sturdy wooden crates supplemented by full reinforcement. This not only safeguards the integrity of the steel during long-distance transportation, but also ensures that it arrives to you in pristine condition, ready for immediate use.

Transportation

FCS overcomes tool steel’s dense/heavy nature and high logistics costs through strategic logistics alliances. Annually shipping bulk volumes globally via partners, we provide real-time cargo tracking—including departure, ETA, and transit updates. Proactively addressing delays from force majeure (weather, congestion), we implement contingency plans like production adjustments or temporary alternatives while maintaining transparent customer communication throughout.

Global OEM TOOL STEEL SERVICE

We provide a one-stop solution from material design to inspection and certification, ensuring that each custom part meets the stringent requirements of industrial applications. Welcome to submit your technical specifications for customized solutions.

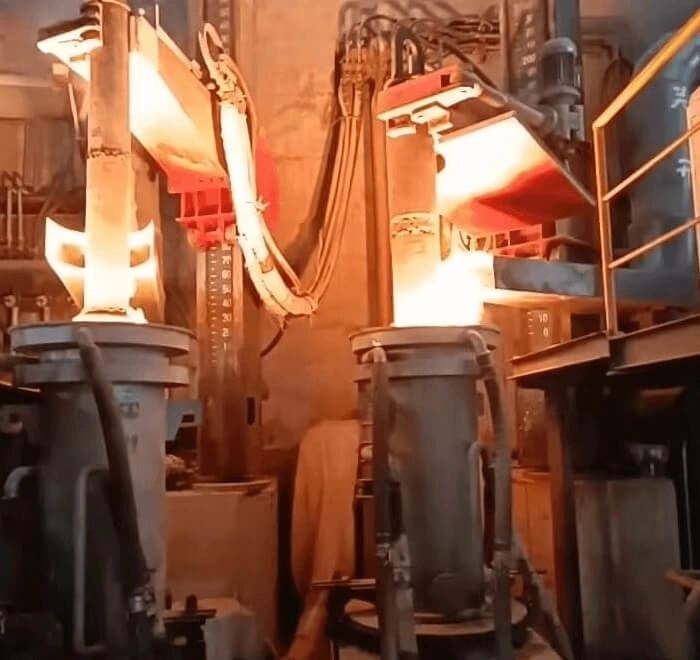

▌ Factory and Production Capacity

FCS TOOL STEEL factory’s main production site occupies 43,000 square meters with the latest metallurgical equipment, including 12 tons EF+LF+VD steel furnace + 6 sets of ESR steel furnace forging line, 3 tons, 6 tons forging hammers. 2 sets of 120 tons natural gas annealing furnaces. Sawing + milling shop with 10 saws + round steel lathes + plate milling lathes. This infrastructure allows a monthly production capacity of more than 2,000 tons, maintaining consistent quality standards in high volume production.

Our FCS plant has separate production lines, as well as a specialized machining department that can custom produce tool steel to the specifications required by our customers. This comprehensive manufacturing capability ensures that we are able to meet your most demanding quantity and quality requirements without compromising on delivery time.

Tool Steel Specifications

Product Customization Options

Customized surface condition

Black; Sandblasted; Grinded; Turned/Machined/Milled/Bright

Customized chemical composition

GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

Customized specifications

Round steel (diameter), plate (thickness, width) can be customized production.

Professional Transportation Packaging

Spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

Customized production

Customized production based on samples or technical agreements.

Full-process site visit

Customers visit the tool steel production workshop, advanced machinery and equipment and efficient warehousing area, intuitively understand the whole chain from production to delivery.

Customized solution docking

The sales team explains product specifications, application scenarios, and focuses on customized solutions to meet specific needs, highlighting market response and service capabilities.

High praise from the client

Testimonials:

“The professionalism, transparency and technical skills are impressive and unrivaled. We are confident in our future cooperation.”

Transparent quality inspection demonstration

- The technical team utilizes cutting-edge equipment to demonstrate the strict quality inspection process on site.

- Customers can witness the strict inspection process of each batch of products from a distance.

- Real-time test results are transparent, strongly verifying product performance, integrity and compliance with high standards.

Appearance and basic performance inspection

- Visually inspect tool steel surfaces for cracks, folds, oxidized skin and other defects to ensure surface integrity;

- Multi-element simultaneous analysis of alloying elements using full-spectrum direct reading spectrometer to verify that the chemical composition meets the standard requirements.

- Using tape measure, high-precision vernier calipers (0.02mm) and other professional gauges, we carry out strict testing of length, diameter, aperture and other dimensions as well as key tolerances of the mating parts to ensure compliance with the contract requirements.

Mechanical and internal quality inspection

- According to SEP 1921-84 Class3 D/d,E/e standard, we use ultrasonic testing equipment to carry out internal flaw detection on the tool steel, to check the macro defects such as cracks, shrinkage holes, inclusions, etc.

- In addition, with the help of metallographic organization analysis instrument, we will inspect the tool steel to ensure that it meets the contract requirements.

- Observe the microstructure with the help of metallurgical organization analysis instruments, and assess the rationality of heat treatment process through grain size rating, to comprehensively safeguard the potential of material mechanical properties and metallurgical quality.

10+

Test content

Visiting activity

Customer Visit Factory

The factory visit provided customers with a valuable opportunity to gain a deeper understanding of our comprehensive strength and commitment to quality, leaving them with an extremely deep impression. Core highlights include:

- Whole chain site visit: Customers visited the tool steel production workshop, advanced machinery and equipment, and efficient storage area, and visualized the complete process from production to delivery.

- Professional solution docking: The sales team elaborated the product specifications, wide range of application scenarios, and focused on customized solutions to meet specific needs, demonstrating strong market response and service capabilities.

- Transparent and Rigorous Quality Control: The technical team demonstrated the strict quality control process using cutting-edge testing equipment. Customers witnessed the meticulous inspection of each batch of products, and the transparent real-time test results provided strong evidence of product performance, integrity and compliance with the highest industry standards.

100%

Customer Satisfaction

NEWS

THE 27th KOREA INT’L DIE · MOLD&RELATED INDUSTRY EXHIBITION

📆TIME: March 11th to 14th,2025

📍Booth No.: M217, Hall 1, Pavilion 2

🏢Add.:217-60,KINTEX-ro,llsanseo-guGoyang-si, Gyeonggi-do, Korea

The International Metal Products and Steel Industry Exhibition of Italy

📆TIME:6th-8th, May, 2025

🏢Booth No.:Hall 22 R5103

Add.: Fieramilano Rho, Strada Statale Sempione28 20017 Rho-Milano,ltaly

Customer satisfaction

Orders

Country of sale

Annual output/Unit: tons

WHY CHOOSE FCS STEEL

We Have Many Parteners All around the world

Optimize your tool’s performance immediately

Take the first step towards achieving manufacturing excellence by consulting with our tool steel experts. Our team will analyze your specific requirements and recommend the best material solution for your unique challenges. Don’t let substandard materials limit your manufacturing potential.

Request a Consultation Today!

“Our company is a large-scale mold manufacturing enterprise with high demand for mold steel and strict requirements on delivery cycles. Over the three years of cooperation with FCS Tool Steel, its stable annual production capacity of 25,000 tons has completely resolved our concerns about raw material supply, and there has never been any order delay caused by insufficient production capacity of the manufacturer. What is even more commendable is that the 2,000-ton standing inventory provides a perfect response to urgent order needs. At the end of last year, we needed an additional 150 tons of SKD11 mold steel for a batch of urgent mold orders. After contacting FCS, they coordinated the inventory and arranged shipment on the same day, and the raw materials were delivered to our factory within 3 days, helping us successfully meet the customer’s delivery deadline. This dual guarantee of “production capacity + inventory” gives us more confidence in the fierce market competition, making FCS a long-term trustworthy partner.”

“As a mechanical parts manufacturer serving the global market, our products need to meet the standard requirements of customers from different countries, which places high demands on the standard customization capability of raw materials. FCS Tool Steel supports customization of multiple standard systems including ASTM, DIN EN, KS, and JIS, which perfectly aligns with our diverse needs. Previously, when we produced a batch of precision parts for Japanese customers, we needed H13 mold steel that complies with JIS standards. FCS not only quickly provided samples that meet the standards but also attached a detailed material testing report, with all indicators accurately meeting the requirements. During the subsequent bulk procurement process, the standard consistency of each batch of products was maintained extremely well, with no quality deviations. This professional customized service has eliminated many worries for us in expanding the international market, resulting in an excellent cooperation experience.”

“In the R&D and production of molds, our company uses various types of tool steel. The multiple popular models supported by FCS Tool Steel, such as SKD11, SKD61, D2, H13, 1.2344, 1.2379, 1.2316, and D6, basically cover all our needs. There is no need to purchase from multiple suppliers, which greatly simplifies the supply chain management process. More importantly, the quality of FCS’s products is extremely reliable. We conduct tests on key properties such as hardness and toughness for each batch of tool steel purchased, and the results consistently meet the standards. The service life of molds produced using FCS’s products is 15% longer on average compared to those using products from other brands, effectively reducing our production costs. In addition, their after-sales team is also very professional and can provide timely solutions when technical problems arise. This dual excellent experience of “product + service” makes us willing to maintain a long-term cooperative relationship with FCS.”

Get In Touch

Address

128 Zhangzhihe Avenue,Hekou Town,Xisai District,Huangshi city,Hubei Province,China